Lincoln Laboratory technologies win five R&D World awards

Ultrasound that doesn’t require touching patients. A web-based tool that reinvents crew scheduling for the Air Force. Cryptographic hardware that protects sensitive data. And the world’s first practical memory for quantum networking.

These four technologies developed at MIT Lincoln Laboratory, either wholly or with collaborators, are recipients of 2023 R&D 100 Awards. The ultrasound technology also received a second award in a special category recognizing market-disrupting products. Bestowed by R&D World magazine, the awards recognize the 100 most significant innovations that have transitioned to use or been made available for sale or license in the past year. The worldwide competition is judged by a panel of science and technology experts and industry professionals.

"Lincoln Laboratory has been very fortunate to receive 86 R&D 100 Awards over the past 14 years. Our rate of unclassified technology transition continues to be very high, and we have a similar high transition rate for our classified programs. The Laboratory is truly changing the world through its successful technology development and transition. We congratulate everyone involved," says Lincoln Laboratory Director Eric Evans.

Medical imaging with noncontact ultrasound

Many people are familiar with the ultrasound process — a sonographer presses a transducer onto a patient’s skin and moves it around, gathering images of tissues and organs. Though a well-established technology, ultrasound suffers from sonographer variability, making it difficult to accurately compare repeat measurements, and is limited by the need to make contact with the skin. For these reasons, magnetic resonance imaging (MRI) and computerized tomography (CT), despite their high costs and lack of portability, are still the predominant imaging technologies for disease tracking.

The Noncontact Laser Ultrasound (NCLUS) for Medical Imaging overcomes these limitations. The skin-safe laser system acquires ultrasound images without touching a patient. It uses a pulsed laser that emits optical energy, which is converted to ultrasound waves upon hitting tissue. The returning echoes are detected by a laser Doppler vibrometer and are processed to generate images. The system’s laser positioning on the body can be accurately reproduced, thus eliminating variability across repeated scans. This repeatability could enable ultrasound to be used to track disease progression, such as changes in tumor size over time.

Its touchless design also opens up entirely new uses for ultrasound: "NCLUS could image burn or trauma victims, patients with open deep-tissue regions directly during surgery, premature infants requiring intensive medical care, patients with neck and spine injuries, and contagious individuals from standoff distances," says Robert Haupt, NCLUS co-inventor.

With NCLUS, medical staff without sonography training might be able to perform ultrasound imaging outside of a hospital — in a doctor’s office, at home, or in a remote battlefield setting. Because of its game-changing potential in the medical imaging industry, NCLUS also received the R&D 100 Silver Medal in the Special Recognition: Market Disruptor Products category, in addition to the R&D 100 Award.

Both awards are shared with the Massachusetts General Hospital Center for Ultrasound Research and Translation and Sound & Bright, LLC.

An optimizer for aircrew scheduling

The U.S. Air Force has intense scheduling needs. Its fleet of C-17s, the cargo aircraft that transports troops and supplies globally, marked four million flight hours last year. Until recently, Air Force airmen, such as pilots and loadmasters, would have to schedule each flight’s crew manually, on a whiteboard.

Puckboard has changed that. The web-based application provides intelligent, training-informed scheduling for the first time since military flight scheduling began about 80 years ago, and is returning valuable time back to airmen to focus on their primary duties.

Puckboard's collaborative tools provide schedulers with assignment recommendations while allowing crew members to volunteer for events that work best for their personal lives. Beyond providing a digital calendaring function, Puckboard applies artificial intelligence (AI) techniques that consider metrics such as crew training progression, flight-hour distribution, overqualification avoidance, and assignment fragility to recommend optimal schedules. Today, Puckboard hosts 24,000 users and has scheduled more than 315,000 events across 87 squadrons.

"Puckboard’s impact is a direct reflection of the breadth and depth of skillsets and sincere passion that all the contributors have. From the designers, software engineers, and algorithm experts to the active-duty squadrons and aircrew members, all the way up to senior leadership — everyone is committed to increasing the readiness of the U.S. Air Force through the lens of improving the quality of life of our airmen," says Michael Snyder, a principal investigator on the project. "Scheduling is a complex topic, made even more difficult under uncertainty, and this effort is a testament to being able to solve any problem with the proper team."

This R&D 100 Award is shared with MIT, RevaComm, Department of the Air Force – MIT AI Accelerator, Air Force 15th Wing, 60th Air Mobility Wing, 437th Airlift Wing, Headquarters Air Mobility Command, Air Force Research Laboratory, Assistant Secretary of the Air Force (Installations, Environment, and Energy), and Raytheon-BBN.

A device to secure data on unmanned platforms

For the U.S. military, the use of unmanned systems is growing to minimize harm to human operators. Because these systems often transmit sensitive data over the air, their radio components must be certified by the National Security Agency (NSA). For years, this certification process has been an insurmountable hurdle for many small businesses and would-be innovators in radio technology and robotics from which the military could benefit. Now, such developers can use an already-NSA certified security solution, developed by Lincoln Laboratory, that’s ready to drop in and deploy for a wide variety of vehicles and missions.

The Security/Cyber Module (SCM) End Cryptographic Unit (ECU) is a compact device that secures tactical datalinks of unmanned systems. The module modernizes security by pulling together multiple cybersecurity technologies, most notably a technique called Tactical Key Management that establishes secret keys on the fly for secure communication. The module is the first crypto device designed for a broad swath of unmanned systems within the Joint Communication Architecture for Unmanned Systems (JCAUS), a recent U.S. Department of Defense effort to modularize unmanned system radio links and allow reuse of NSA-certified components by standardizing capabilities and interfaces.

Since its delivery, the U.S. Navy has awarded a full-rate production contract to Tomahawk Robotics to supply SCM ECUs for use in their explosive ordnance disposal robots. "While developed primarily for Navy ground robotics, the SCM/ECU’s adherence to JCAUS ensures that it is well suited to airborne and underwater vehicles alike," says Ben Nahill, a principal investigator on the program.

The award is shared with the Naval Information Warfare Center Pacific.

A scalable, photonic memory for quantum networking

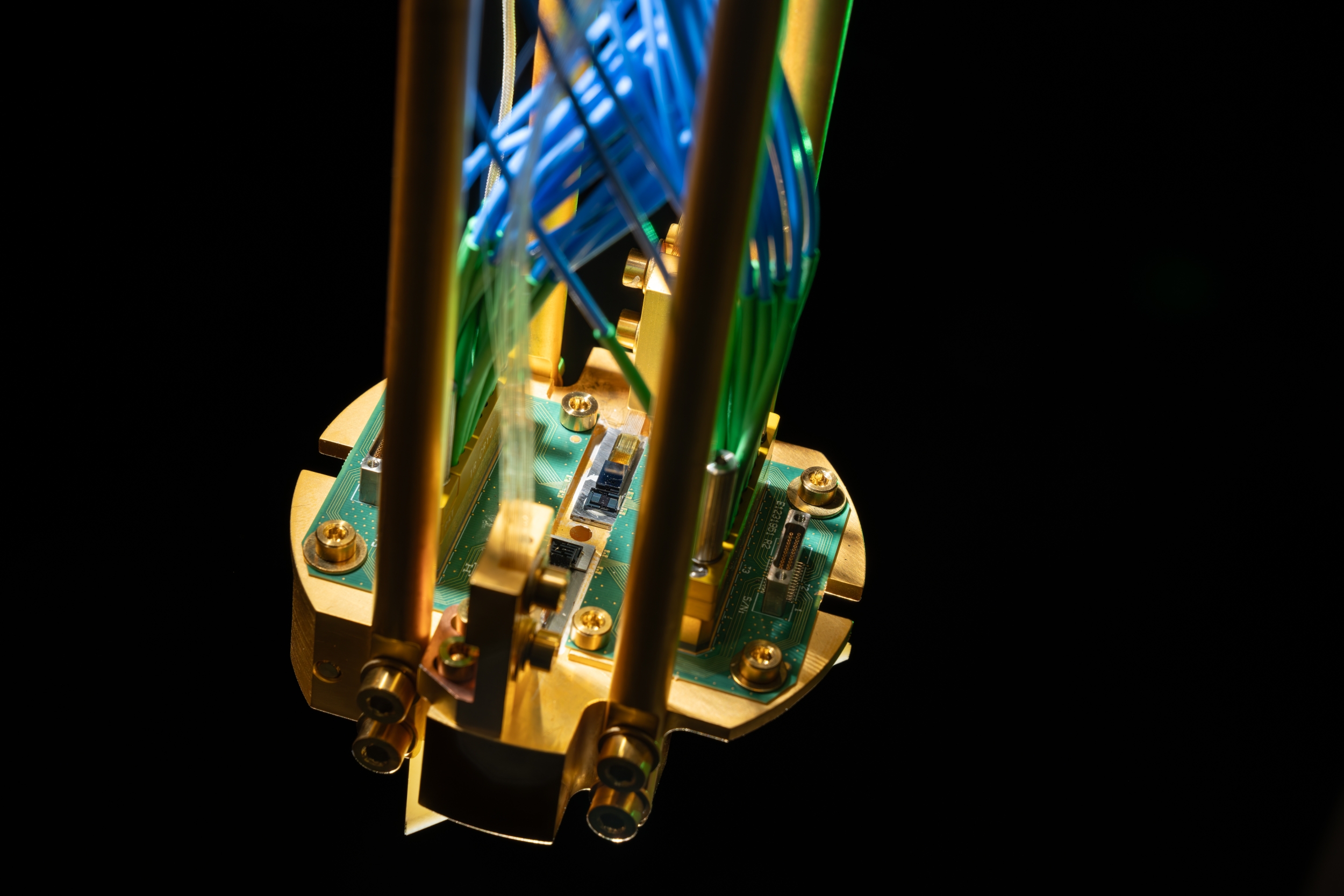

In quantum information processing, memory receives and stores the state of a quantum bit (qubit), similar to how memory for an ordinary communication system or computer receives and stores information as binary states. Memory makes it possible to reliably send and receive information between separate systems, even across lossy transmission links. Lincoln Laboratory’s quantum memory is the first to combine, into a single module, the three capabilities required for networking together separate quantum systems: a photonic interface, a way to correct for loss errors, and an architecture scalable to tens of memories in a single module. Until now, quantum memory systems have fallen short on one or more of these capabilities.

"This module eliminates many of the barriers to deploying quantum memories into real-world settings and testbeds and to actually using them to develop emerging advanced quantum applications, such as distributed sensing and networked quantum processing," says Ben Dixon, who leads this work.

A photonic interface allows for qubits to be transferred via particles of light (photons) between the memory and optical-fiber networks. The Laboratory’s quantum memory uses silicon-vacancy (SiV) diamond color-centers, which are atom-like structures that can be efficiently manipulated with light even at the single photon level. This SiV technology can also correct for signal-loss errors resulting from inefficient and lossy network links. Because it makes use of individual atomic color-centers, this technology is compatible with efficient "heralded" protocols, where a signal confirms the successful transmission of a photon across the network and storage of the associated qubit in memory.

The SiV module is also scalable. The SiV memory cells are integrated to a custom-made photonic integrated circuit, a technology that enables sending and receiving signals and can be scaled to hundreds of parallel channels. Combining this integration approach with a unique packaging architecture, Laboratory researchers integrated eight quantum memories into a single module. Additional memories can be integrated into this single module, which can be joined with additional modules for further scalability.

In addition to these winning technologies, five other Lincoln Laboratory technologies were named R&D 100 Award finalists. A gala celebrating the 2023 award winners will be held on November 16 in San Diego, California.

Inquiries: contact Kylie Foy.