Lincoln Laboratory celebrates the opening of the Defense Fabric Discovery Center

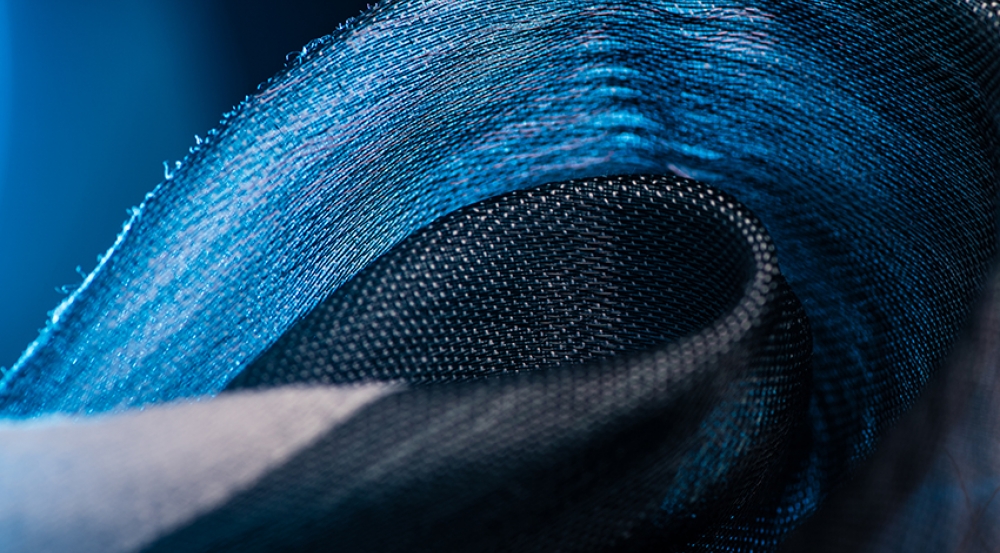

In a small industrial building at MIT Lincoln Laboratory, a 20-foot fiber draw tower is steadily pulling a strand of plastic and winding it around a large spool. To the untrained eye, it looks like an ordinary thread, but the fibers made at Lincoln Laboratory's newly opened Defense Fabric Discovery Center (DFDC) are anything but ordinary. The end-to-end prototyping facility is equipped to design and produce fabrics that can change color, store energy, emit and detect light, monitor health, or facilitate communication.

On 27 October, the Laboratory welcomed more than 120 guests to see this new technology in action at the DFDC ribbon-cutting ceremony. The event featuring speeches from prominent contributors to the project, exhibits from local textile and fiber manufacturers, and tours of the new facility.

"We have now a very advanced prototyping facility. We are producing fibers and creating complex new systems to be embedded. We can weave them into the fabrics, and we can do that very rapidly," Eric Evans, Lincoln Laboratory director, said at the ceremony. "We could revolutionize the fabric and textile manufacturing industry in the region, in the country, and maybe even around the world."

The DFDC was born of a collaboration between the Laboratory, U.S. Army Natick Soldier Systems Center, Commonwealth of Massachusetts, and Advanced Functional Fabrics of America (AFFOA). AFFOA is a non-profit founded by MIT, funded in part by the Department of Defense through the Manufacturing Technology Program, that is working to accelerate fiber and fabric innovation. The DFDC is one of a network of fabric discovery centers founded by AFFOA and is the first to focus on the defense applications of advanced fibers and fabrics.

One project the DFDC will work on is improving soldiers' uniforms. Depending on their operational role, soldiers may be required to carry more than 100 pounds of protective clothing, weapons, and gear. This weight can compromise the effectiveness of a warfighter. Despite the bulk, the equipment still fails to account for some of the soldiers' needs on the battlefield, such as health monitoring and energy production and storage. By integrating advanced sensing, energy, and communication microelectronics into the fabric of soldiers' uniforms and gear, DFDC researchers could create lightweight solutions to these needs.

To develop fabrics with electronic capabilities, the DFDC is equipped with several tools: CAD software for modeling the fiber preform that contains the microelectronics, a draw tower to pull and spool the fiber, a full-garment knitting machine to weave the fiber into fabric, and system integration technology to produce a finished product. The ability to complete all the prototyping steps under one roof will speed up the process of getting finished products to the Department of Defense for operational use, a point which several speakers at the ceremony emphasized.

"Our work could mean the difference between victory and defeat for our army on the battlefield and between life and death for our soldiers," said Brigadier General Anthony Potts, Deputy Commanding General, U.S. Army Research, Development and Engineering Command.

The Commonwealth of Massachusetts, which contributed funding for the equipment in the DFDC, had an additional goal in building the center: to create jobs and re-establish domestic textile manufacturing. The DFDC will partner with local business to develop products.

"The knowledge that we gain by actually doing that advanced manufacturing ourselves leads us to the next generation of innovation," Ira Moskowitz, director of the Advanced Manufacturing Programs Innovation Institute of the Massachusetts Technology Collaborative, said in a speech at the ceremony. "As a state and as a country, we cannot continue to innovate here and maintain our technological leadership if we continue to send our technology overseas for manufacturing."

The center will not only benefit the Laboratory, which previously did not have the facilities or equipment to work in advanced fabrics, but also the many AFFOA-affiliated organizations with which the Laboratory partnered for this project.

"We'll be working with many of you around the room who are part of the AFFOA program to make sure that you can work through Lincoln Laboratory and the Natick Soldier Systems Center to have a classified conduit into the defense world," Evans said to the audience at the ribbon cutting. "We will help you understand defense needs and get things moving very very quickly."

The DFDC went from an idea to reality in only seven months, including four months of extensive construction on the building by the Facility Services Department. Within the next six months, the center will be expanding further to include a full-sized loom for weaving fabrics and a second draw tower, which will be capable of drawing optical fibers. Laboratory staff are already making use of the DFDC, drawing fibers with embedded light-emitting and light-detecting devices and investigating how to integrate them into fabrics.

"We have a very unique opportunity in front of us. Just as advances in semiconductor chip manufacturing over the past 50 years enabled a technological transformation and really a transformation in the human experience, so too can advances in fiber devices and fabrics," said Alexander Stolyarov, a technical staff member in the Laboratory's Chemical, Microsystem, and Nanoscale Technologies Group and the lead on the DFDC initiative. "We are just at the beginning, only starting to imagine what a fabric could do if it's packed with all the stuff of technology. How can you not be excited?"