Lincoln Laboratory intern develops cost-management software for 3D printer

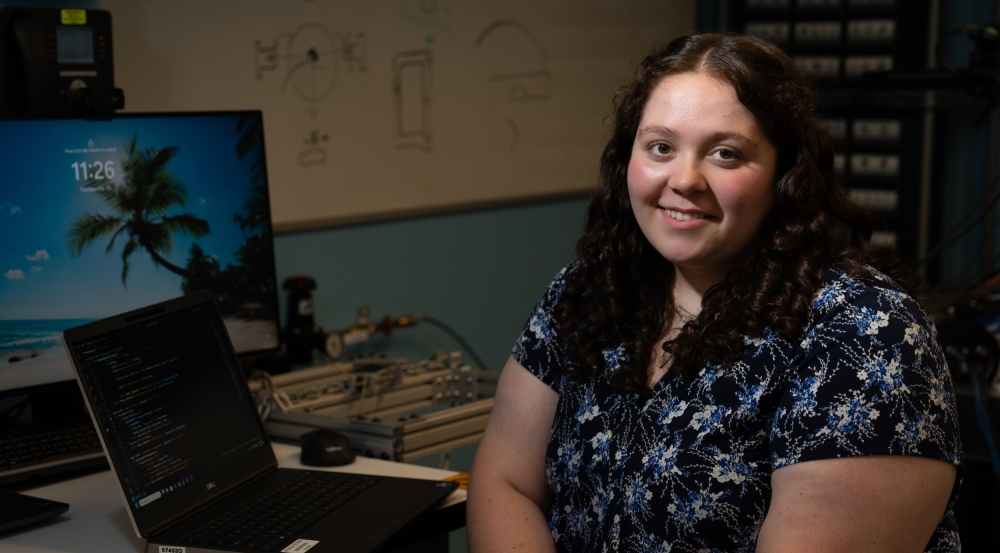

High school graduate Riley Harn interned this year in the Laboratory's Mechanical Engineering Group through the Armed Forces Communications and Electronics Association (AFCEA) International’s Fellowship Awards Program. The Lexington-Concord Chapter of AFCEA selects high school seniors to work with partner organizations to gain experience working in a professional environment prior to entering college. The Laboratory hosts interns from this program each summer, embedding students in groups to work with technical staff mentors. Harn, who graduated from the Massachusetts Academy of Math and Science at Worcester Polytechnic Institute, was one of 40 students selected for this year’s program.

As soon as she arrived at the Laboratory, Harn was immersed in an environment full of new information to learn. "I liked going to all of the seminars that the Laboratory hosted for the interns. I think I've been to almost every single one of them," Harn says. She began bringing a notebook with her, and by the end of her three-month internship, the notebook was filled with facts and questions she had jotted down during each seminar. "At the start of my internship, there were a bunch of lectures that were open to more than just the interns. I went, and maybe I didn't always know everything that was going on, but it at least exposed me to [new subjects]. It prompted me to go home and say 'What is this?' and learn what different things are."

The Laboratory regularly holds seminars, open to the Laboratory community, that discuss ongoing Laboratory projects. One of the seminars Harn attended gave an overview of the work conducted by the Laboratory’s Engineering Department, where Harn was assigned as an intern.

Harn's task during her internship was to optimize a 3D printer in one of the Mechanical Engineering Group's laboratories. She wanted to figure out how to automate the printer’s cost-management system. Because multiple users shared the printer to make parts for their prototypes, mapping each charge number to its associated print job was difficult. Before Harn tackled the problem, group staff members manually kept track of printing costs, which was time consuming and tedious.

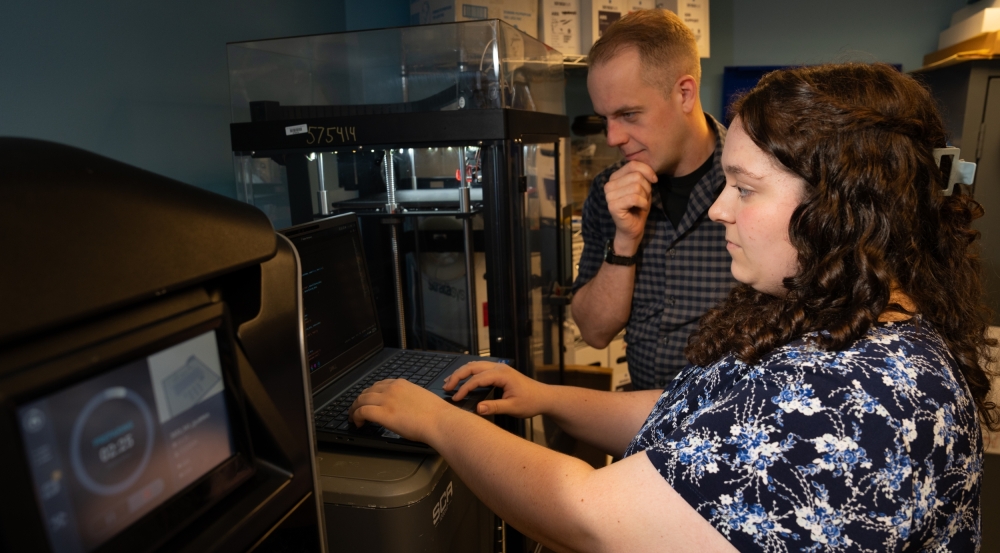

"You could pull up GrabCAD* and see how much filament somebody used, but it's a lot easier to set the printer up so that the charge number automatically goes with the print job," Harn says. "I did this in code and set up a system that emails people so they can submit their charge number and also connect to the printer over the network, which was the biggest challenge."

"It was during Riley’s approach to this problem that we discovered her extensive programming skills and found in her a rather tenacious drive to solve her way through the various coding, network communication, and information security–related impasses that she encountered along the way," says Rob Reeve, Harn's mentor in the Mechanical Engineering Group.

As a high school student, Harn participated in the For Inspiration and Recognition of Science and Technology (FIRST) Tech Challenge, a competition that challenges students to build and code robots. This experience sparked her interest in mechanical engineering, which she plans to study in university. Though Harn had extensive experience coding for FIRST competitions, her internship project challenged her skills to a new level. "I had coded in Python before, but this was next-level Python. Connecting over the printer and getting data from the printer was definitely challenging," Harn says.

Despite the technical challenges, learning to apply her knowledge of coding to a new problem was a valuable learning opportunity, Harn says. "I really like robotics, so getting more experience in programming — and in general, seeing how things at the Laboratory work — was great. Learning that there is a laboratory where staff perform prototyping has also been cool and relevant to what I want to do [in college]."

By the end of her internship, Harn built a cost-management software that communicates directly with the 3D printer to track what and how much materials are used for a print job. The software then sends emails to users to request cost-assignment information, and automatically produces cost-assignment reports on a biweekly basis, greatly streamlining the laboratory's 3D-printing system.

"The software Riley built was impressively functional, and the interface looked very clean and professional," Reeve says. "She was an excellent intern — a 10 out of 10."

In addition to making a lasting improvement on the Laboratory's prototyping processes, Harn left her internship with new skills that she believes will be useful in future academic and professional settings. "I gained hard skills — like learning how to connect to something over a network using Python, and being able to parse through that data — and soft skills, like being able to be in an office environment and talk to people," Harn says. "I'm grateful to have been able to have this experience and grateful to Lincoln Laboratory and AFCEA."

*GrabCAD is a cloud-based software that helps manage 3D printing jobs.