Scientists look to synthetic biology and 3D printing for life support in space

As NASA gears up for sending humans back to the Moon or even to Mars, they'll need to figure out how to keep these humans healthy and safe far away from the resource-abundant Earth. It won't be feasible to pack everything they may need over the course of the mission, and resupply missions like those that keep the International Space Station (ISS) stocked will be prohibitively expensive and lengthy.

What these astronauts can pack are Earth's unique renewable resource: cells. Those of fungi and bacteria, for example, can be reprogrammed with synthetic DNA to produce specific materials, like bioplastics. These materials can then be fed into 3D printers to manufacture things they may need during spaceflight — everything from hardware and medical devices to medicine and food.

In an opinion piece published online on July 11 in Trends in Biotechnology, researchers from the Universities Space Research Association (USRA), MIT Lincoln Laboratory, and NASA outline ways that synthetic biology and 3D printing can support life during deep-space human missions. But to make these ideas a reality, NASA is seeking help.

"Our opinion piece is a call to action to get DIY [do-it-yourself] biology and makerspace communities involved," said Peter Carr, who works in Lincoln Laboratory's Bioengineering Systems and Technologies Group. The DIY biology community makes it possible for anyone in the public with an interest to conduct biological engineering. The community operates outside of the traditional academic or industry settings and spreads knowledge through open sourcing. Many DIY biologist groups operate makerspaces that provide equipment and supplies for members to do experiments on their own.

"These separate, eclectic communities do bio in unconventional settings all the time and are pioneers at rapid prototyping and developing technologies with limited resources. There are parallels here with space and the needs of NASA crews," Carr said. "But this also requires organizations like ours and NASA to connect more deeply with them in a two-way process, so there's a real pathway to getting people's work into space. We're just getting started."

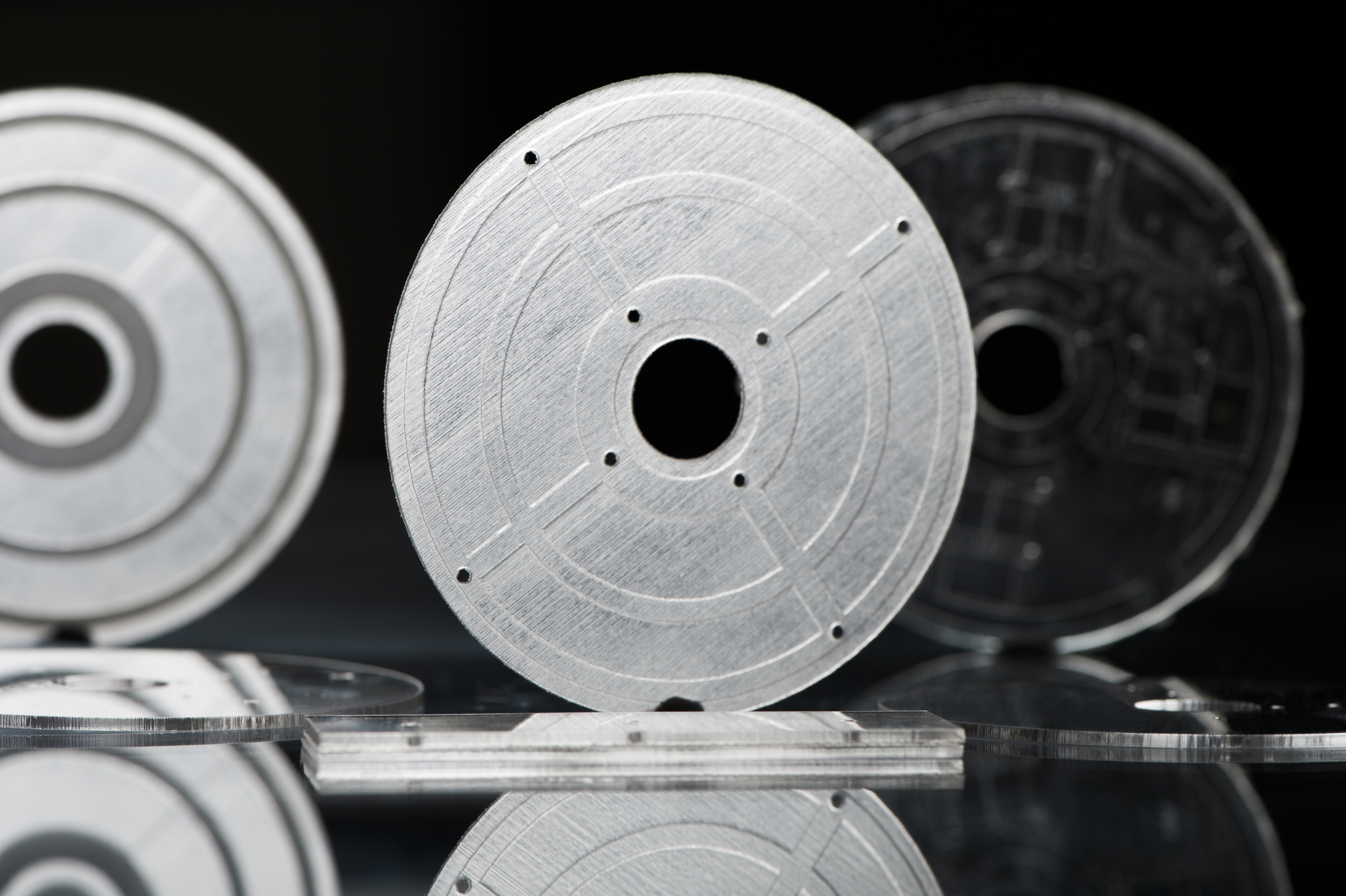

3D printers are common staples of makerspaces. Experiments done on the ISS with 3D printers have proven their utility for manufacturing on-demand items, like replacement hardware. But if 3D printing is to be a reliable tool for long-duration missions in space, a new problem crops up: the need to supply the ship with the feedstock for the printers.

To meet this need, the authors envision using synthetic biology to produce custom, biological "ink" to 3D-print whatever may be needed over the course of a mission. Such a process would give scientists "the autonomy to design for the unknown," said Jessica Snyder, a USRA researcher who leads the synthetic biology task for the NASA Academic Mission Services.

Living organisms can convert sunlight, nitrogen, and water into finished products. Bioengineers can reprogram the inner logic of these organisms' cells to produce target compounds. The building blocks to edit these cells can be digitized and sent to the space crew in the form of a DNA sequence, which can be synthesized, assembled, and inserted into an organism on-ship. "The idea is what we call a 'bits-to-biology' converter," said David Walsh, a bioengineer at Lincoln Laboratory.

We often hear about the engineer who was inspired by NASA in their youth, and works there now. But what about the bio people who are inspired by these grand ideas? How can they contribute? Now is a chance to transition their ideas to space.

Here's one example how this vision could be implemented. Say astronauts faced a situation that occurred on the ISS in 2007: a solar panel has torn and needs a repair strap. On Earth, synthetic biologists, whether of the DIY type or not, design and test genetic programs instructing bacteria to produce the polymer feedstock for 3D printing. (This work could also take place well before the need arises during the space mission.) The maker community works out the design of a strap from those materials. These genetic instructions and 3D printing instructions are sent digitally from Earth to the space crew. The crew reproduces the genetic program, and the bacteria reproduce and synthesize the raw materials, which are used to 3D print the strap. At the end of the product's life cycle, the part is recovered and digested and a new one can be made.

"We have the power of digital information. We can design and work out all of the kinks on Earth and simply send the instructions to space," Walsh said.

The same principles can be used to insert DNA into organisms in space to make target compounds for food or pharmaceuticals, which if brought directly from Earth would degrade over time from radiation in space.

Astronauts would be able to conduct these complex biology experiments by using 3D-printed microfluidic devices. These tiny "lab-on-a-chip" devices automatically control the flow and mixture of fluids through microchannels and use only trace amounts of chemicals to run hundreds of bioreactions in parallel in seconds. Genetic instructions would be sent directly to electronics controlling these microfluidic devices, enabling them to precisely follow the digital "recipe" to synthetize molecules of DNA.

Earlier this year, Lynn Rothschild, a scientist at the NASA Ames Research Center who coauthored the opinion piece, led a team that ran the first synthetic biology experiments in space. The experiments aimed to test how well bacteria in space take in synthetic DNA inserted into their genome and how well the bacteria produce proteins, while being spun to simulate microgravity (what astronauts in the ISS encounter), lunar gravity, and Martian gravity levels. The experiments took place on the PowerCell payload aboard the German satellite mission Eu:CROPIS (Euglena and Combined Regenerative Organic-Food Production in Space).

There is still a long way to go, however, both in experimenting with synthetic biology and figuring out all of the parameters that would make 3D printing with biomaterials possible in space. "For example, bacteria will need water and will take up space; They need the right environment to live and they'll produce waste. We still need to put these ideas up against the real-world constraints," Carr said.

But there's urgency in developing the concepts now. If synthetic biology and 3D printing techniques can be proven and practiced in time for missions close to Earth, where supplies can still be sent relatively quickly from, then they can be counted on for a long-term mission to Mars.

"Flexible manufacturing techniques provide an excellent complement to Earth-based supply chains for destinations days away, like the International Space Station and possible lunar infrastructure for examples. Let's take advantage of this redundancy to build an in-space manufacturing capacity to take us further into space more safely," Snyder said.

Do-it-yourself biologists and makers can help today by publishing their designs for 3D-printed products, microfluidic devices, or synthetic DNA on open-source repositories and by testing and editing published designs. "If DIY bio communities use, iteratively improve, and ultimately approve of a technique, then that technique has been optimized more robustly than most individuals or team could offer without great effort. Partnering with these communities is an invaluable asset," Snyder added. People who are interested can also see NASA's Centennial Challenges, which outline problems that NASA is seeking the public's help to solve.

"We often hear about the engineer who was inspired by NASA in their youth and works there now. But what about the bio people who are inspired by these grand ideas? How can they contribute? Now is a chance to transition their ideas to space," Carr says. "There is so much opportunity to innovate."