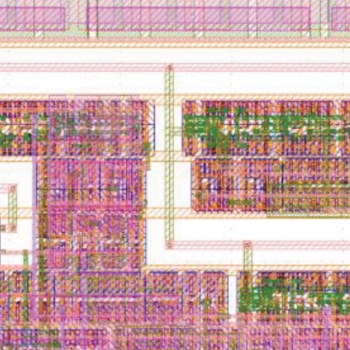

Defensive Routing and Related Techniques

Integrated circuits (ICs) are central components of modern-day electronic devices. However, the fabrication of ICs poses a potent security risk as they are vulnerable to attacks during creation. Because these attacks against security-critical wires can potentially leak vital information, invalidating the entire purpose of the IC, there is a need for defensive routing methods. Current defensive methods are typically reactive and provide security at a late stage, leaving a window for attacks during fabrication. Furthermore, traditional methods mainly focus on protecting the entire IC rather than on targeting the security-critical wires that often hold the most vital information and pose greater risk. This focus makes these current methods rather inefficient and leaves room for security vulnerabilities.

Technology Description

Defensive routing involves creating a secure, preventive layout for security-critical wires, inhibiting fabrication time attacks in an integrated circuit (IC). This refined method includes identifying security-critical wires in an IC design, finding any unblocked surfaces, and protecting those surfaces with a guard wire. The guard wire, which could either be natural or synthetic, is positioned strategically around the surfaces of security-critical wires as a critical defensive shield. The technology differentiates itself by taking a proactive, routing-centric approach to securing against IC wire attacks during fabrication. It reduces the vulnerabilities of the design, especially during fabrication, by securing the surfaces of identified crucial security wires with a guard wire. Its dual consideration of natural and synthetic guard wires further underscores its flexibility and robustness in defense.

Benefits

- Proactive and preventive securing of ICs during the fabrication process

- Focused protection of security-critical wires holding vital information

- Flexibility offered with usage of either natural or synthetic guard wires

- Reduced chances of information leakage through fabrication time attacks

- Potential for improved credibility and trust in electronics manufacturers

Potential Use Cases

- Use in manufacturing computer processing units and other hardware devices involving ICs

- Application in the telecommunications industry for safer creation of communication chips

- Use in medical device production, specifically those devices that leverage IC technology

- Implementation in military and defense electronic systems

- Integration into automotive industry, particularly in the production of automotive microcontrollers