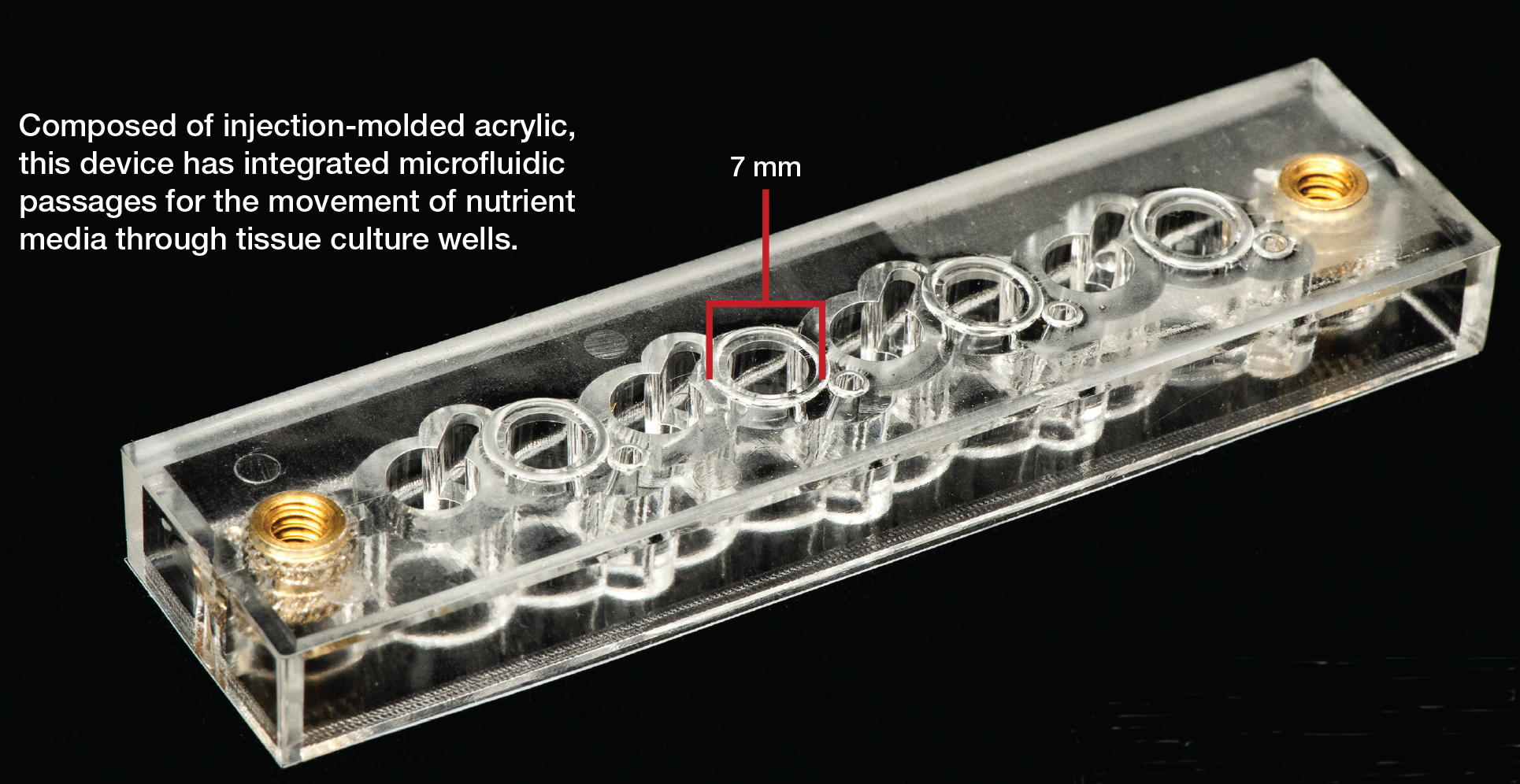

High-Throughput Vascularized Tissue Culture Device

This unique device automates the vascularization of human tissue in the neurovascular unit, the complex network of cells and blood vessels sustaining brain function, by combining high-throughput tissue culture with vascularization support. This capability is not possible in static tissue culture. Initial testing has demonstrated promise in the development of a mature model to study the physiology of the blood-brain barrier (the body's unique system of brain microvascular endothelial cells that nourish the brain and shield it from toxic substances).

Case Study: Neurovascular Unit

In this custom system, the well contains a "bio ink" gel containing brain cells (astrocytes and pericytes) and blood vessel cells (endothelial cells) into which media flows to induce the shear (friction from blood flow) required for vascular development. Tubing fits into a "fluidic ribbon connector"—a single-piece manifold that places the inlet tubes for each well and seals the top of every well to enable the pressure seal without which the flow would not move through the bio ink. Flow switching ensures automated reproducible flow through each well separately.

Potential Uses

The design of the neurovascular device can be translated to platforms for the co-culture of other in vitro models of human tissue, enabling a range of research applications:

- Basic research: the platform identifies how perturbations to cells impact tissue function or how different tissues communicate and impact each other

- Regenerative medicine: the platform enables the culture/growth of cells that require communication with other cell types

- Drug screening and development: the co-culture platform can demonstrate human tissue's response to drugs or determine the impact of drugs as they pass a barrier tissue to arrive at their targets

Benefits

- Tunable shear flow (pressure caused by a fluid's motion) supports living tissue maturation and development for various experiments or applications

- Fully integrated fluidics system enables leak-proof, individually programmable tissue cultures

- Device is scalable to a standard 96-well plate and is easy to integrate into existing automation workflows

- 3D printing of prototypes enables low-cost rapid development; prototype is easily transitioned to injection molding for final manufacturing

Potential Use Cases

- Research

- Medical applications

- Drug development

Additional Resources

Patent application 20210062128A1