Multilayered Microhydraulic Actuators

Traditional motors and actuators have certain limitations, such as high power consumption, large size, and low control fidelity, hindering their effectiveness in various applications. There is a need for compact, energy-efficient yet powerful actuator technologies that can be employed in diverse systems such as robotics, aerospace systems, and medical devices. Existing actuator technologies, such as piezoelectric, shape memory alloys, and electromagnetic, suffer from issues like high voltage requirements, limited force generation, high complexity, or costly materials. As a result, these limitations constrain their versatility and applicability in many domains where precise, low-voltage actuation is essential.

Technology Description

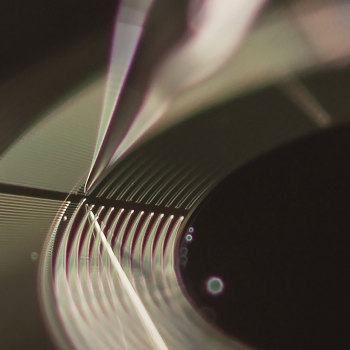

The multilayered microhydraulic motor utilizes microhydraulic technology with electrowetting to distort liquid droplets pinned to a structure, providing low-voltage, high-torque, and efficient actuation. By stacking multiple microhydraulic layers with electrical connections, the motor achieves greater force compared to single-layer motors. The technology stands out for its multilayer design, enabling more powerful and precise actuation while maintaining low voltage requirements. This design is suitable for a wide range of applications, including robotic joints, uncrewed aerial vehicles, medical devices, consumer electronics, and reconfigurable materials. The actuator comprises two adjacent layer structures with liquid droplets between them and electrodes on the second layer.

Benefits

- Low-voltage operation for energy efficiency

- High-torque output for powerful actuation

- Compact and scalable design for diverse applications

- Greater force generation resulting from the multilayer structure

- Potential for precise control and high fidelity

Potential Use Cases

- Robotic joints in humanoid and robotic arms

- Uncrewed aerial vehicles, for precise wing and rudder control

- Medical devices, such as microsurgical tools or drug delivery systems

- Consumer electronics like wearable devices and haptic feedback systems

- Reconfigurable materials for adaptive structures and prosthetics