Thermal Isolation in Polymer Fiber

The field of thermal management and control in materials is highly important for a range of industries, often necessitating solutions that can insulate materials from their surroundings while maintaining specific temperatures. Furthermore, heat exchange between fluids is a critical process in many applications such as HVAC systems, power plants, and refrigeration units. The need for such technology like the drawn polymer fibers comes from the demand to improve thermal regulation and fluid-flow management within these systems. Traditional heat insulation materials and heat exchangers often suffer from inefficiency or lack of versatility. For instance, insulating materials may not provide satisfactory thermal isolation or require extensive resources for temperature control. Simultaneously, typical heat exchangers may not allow for modifiable fluid direction or efficient heat transfer. These issues highlight the need for a technology that can adeptly manage both thermal insulation and fluid heat exchange.

Technology Description

This technology is a type of drawn polymer fiber that is uniquely designed with internal channels. The channels run either partially or completely through the length of the fiber, allowing the fiber to act as a thermal isolator that insulates the central core material from the external environment. These channels serve both insulating and heating or cooling capabilities, depending on needs. Fluid can be pumped through the channels to manage the fiber's core temperature. Moreover, such fibers are versatile enough to be used as various types of heat exchangers: recuperative, regenerative, parallel-flow, counter-flow, cross-flow, or condenser/evaporator. In this application, the channels guide the flow of fluid, permitting efficient heat exchange between fluids in the internal channels. Its unique design allows for advanced thermal management and heat exchange, distinguishing it from conventional fibers.

Benefits

- Provides thermal isolation and temperature control

- Acts as heat exchanger, allowing efficient heat transfer

- Allows fluid direction to be modifiable within the fibers

- Promotes energy efficiency because of the improved thermal regulation

- Offers great versatility in application

Potential Use Cases

- Used as insulating material in construction for effective thermal isolation

- Applied in HVAC systems to efficiently regulate temperature

- Used in power plants for managing heat exchange

- Implemented in industrial refrigeration units to maintain temperatures and allow for heat exchange

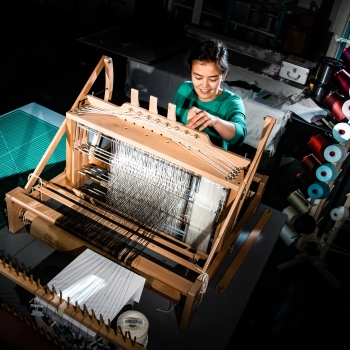

- Applied in the textile industry to manufacture thermal regulating fabrics