Lincoln Laboratory researchers develop a fabric that can sense chemical vapors

Many people may recall using pH (or litmus) paper during high school chemistry experiments. The litmus test is a quick method of determining whether a liquid is acidic or basic by dipping a paper strip into the liquid and then observing the resulting color change.

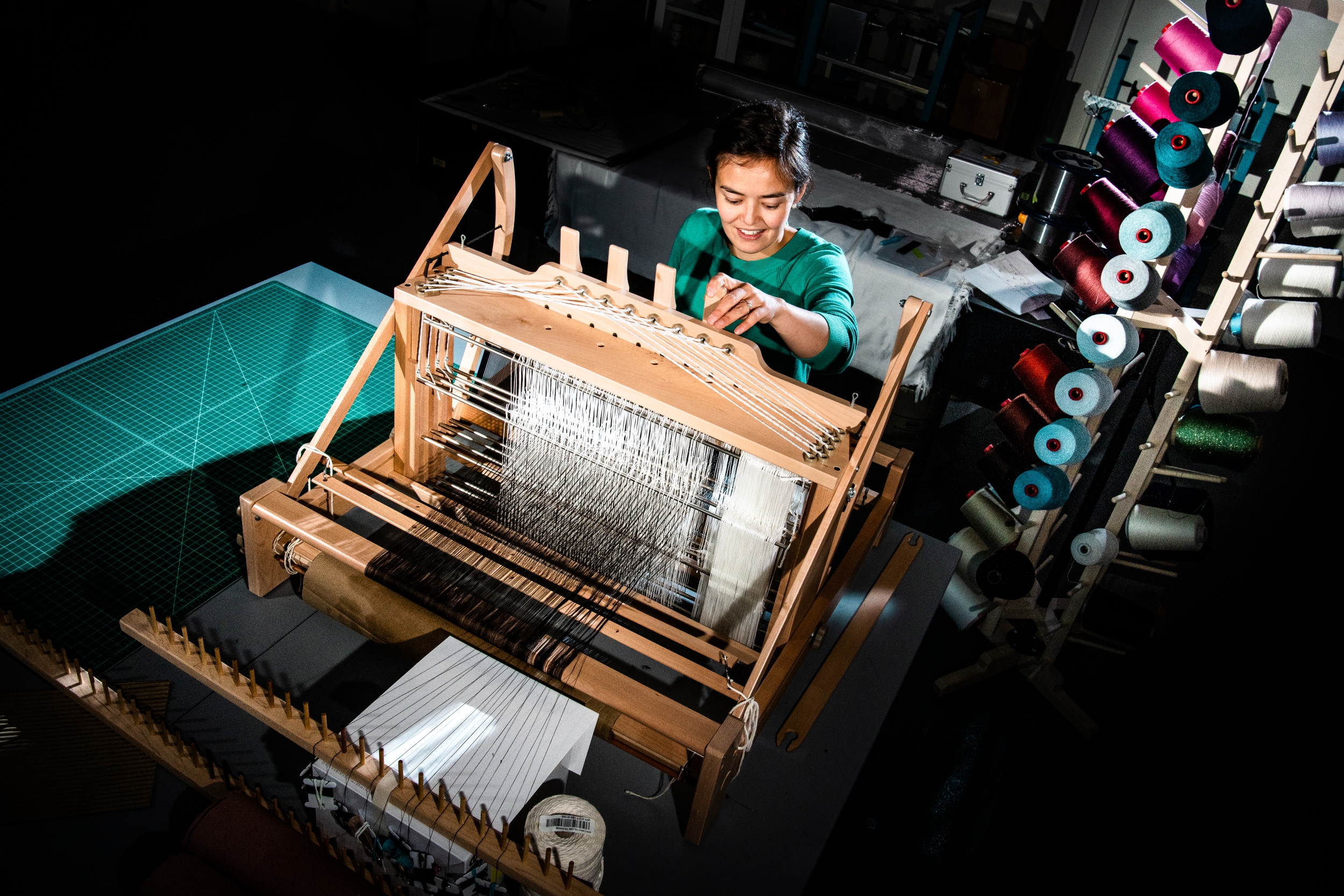

Now, researchers in Lincoln Laboratory's Chemical and Biological Technologies Group and Advanced Materials and Microsystems Group are using a similar color-changing technique while developing a self-reading "pH fabric" that could help warn of dangerous chemical releases.

The fabric sensor is highly sensitive to chemical vapors and can automatically alert personnel wearing the fabric to the presence of harmful chemical vapors. This technology could help address the evolving threat of chemical releases, including those from industrial incidents or terrorist attacks.

"We are developing a unique, wearable fabric-based spectrometer that can detect the presence of a variety of chemicals in real time based on color-changing dye chemistry," said Richard Kingsborough, a member of the technical staff in the Biological and Chemical Technologies Group. "The goal is to build a sensor that is sensitive, lightweight, low power, and autonomous, yet provides that early warning that could save lives."

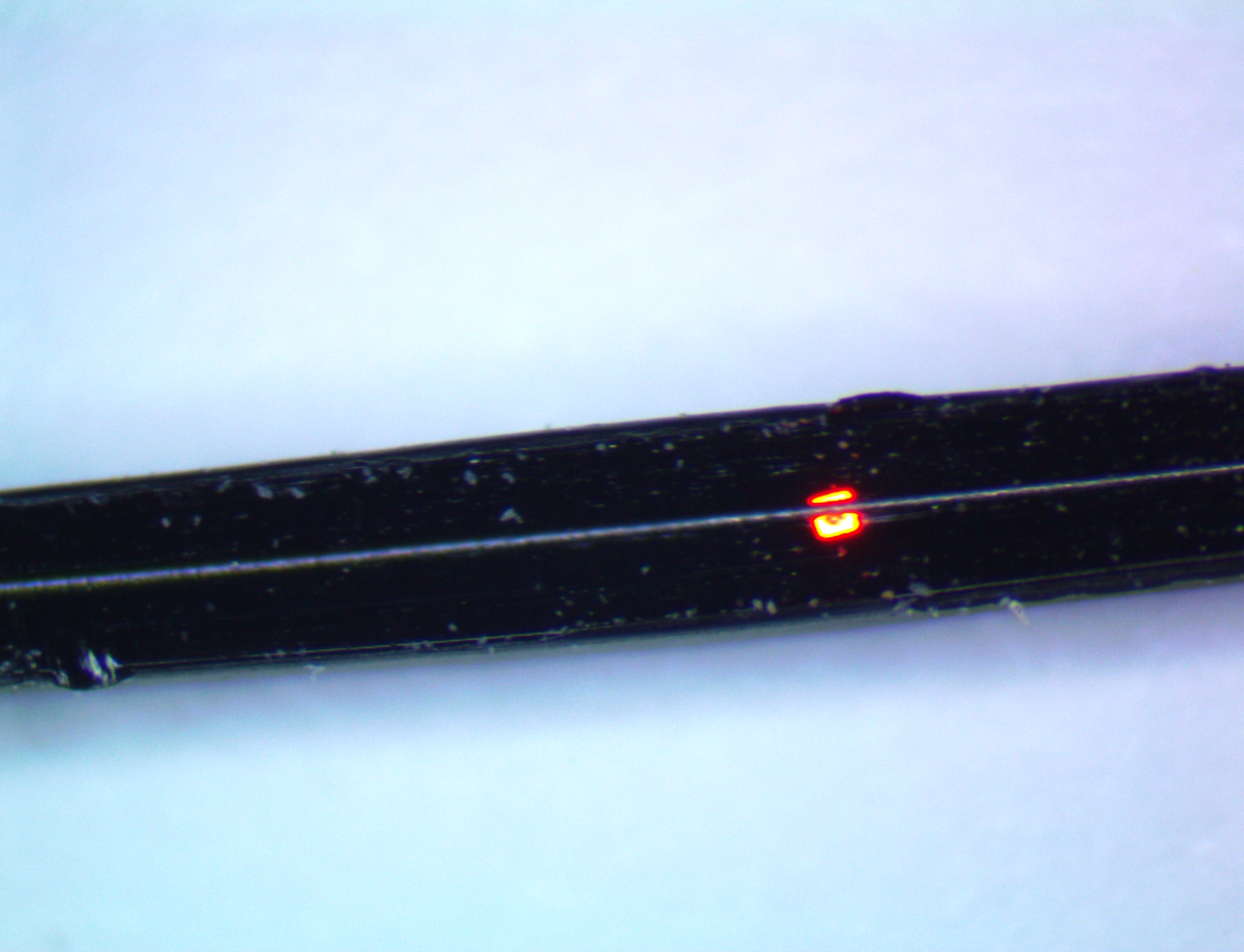

The fabric spectrometer is made by embedding a transmitter (in this case a light-emitting diode, or LED) within a polycarbonate fiber and a receiver (or photodiode) within a second polycarbonate fiber. These fibers are then woven into a fabric in such a way that the LED is positioned next to the photodiode.

"There are a breadth of programs integrating semiconductor devices within a fiber," said materials scientist Lauren Cantley. "While this program also integrates LEDs into the fiber, what is unique is the need to specially formulate the properties of the polymer materials that we use. Most other programs are using off-the-shelf thermoplastics, whereas here we are formulating our own polymers in order to control the optical absorption properties of the material."

After the LED and photodiode fibers are woven into a fabric, a substrate containing the color-changing dye is placed directly on top of the fabric. When operating, the LED shines light onto the dye layer, and a certain amount of light is reflected back and picked up by the photodiode. The amount of light that is reflected depends upon the color and absorption characteristics of the dye.

When the dye is exposed to a chemical agent, the dye changes color, and this color change subsequently alters the amount of light reflected from the fabric. For example, a pH-sensitive dye that changes from yellow (the acid form of the dye) to blue (the base form of the dye) can signal the presence of ammonia vapor, a basic chemical compound. That change is observed as a decrease in the red light that is reflected by the substrate.

This fabric spectrometer has the advantage of continuously monitors the wearer's surroundings and can give autonomous notification if it senses a chemical.

This system has already proven successful in detecting chemicals such as ammonia and formaldehyde. The research team's ultimate goal is to develop a two-inch-by-two-inch fabric patch that features a 16-element matrix, which would be able to identify all of the chemical warfare agent classes as well as a large selection of toxic industrial chemicals.

"I am very excited that we are working on a new way to provide early warning for the detection of chemical agents," said Kingsborough.

This research builds upon recent advances in fiber technologies and functional fabrics made possible through the Laboratory's Defense Fabric Discovery Center. At the center, staff have been experimenting with colorimetry — a process that performs chemical analysis via a color-changing chemical reaction — for several years through two investigative efforts, one funded by the Defense Threat Reduction Agency and another funded by the Advanced Functional Fabrics of America.

"This program provides a new technology for general awareness of chemical threats," said Roderick Kunz, who is the assistant leader in the Chemical and Biological Technologies Group. "This is a much-needed capability that private industry has thus far failed to deliver. In that regard, it is a perfect fit for the Laboratory's mission of technology in support of national and homeland security.