Small, inexpensive hydrophone boosts undersea signals

Lincoln Laboratory has developed a first-of-its-kind hydrophone built around a simple, commercially available microphone. The device, leveraging a common microfabrication process known as microelectromechanical systems (MEMS), is significantly smaller and less expensive than current hydrophones, yet has equal or exceeding sensitivity. The hydrophone could have applications for the U.S. Navy, as well as industry and the scientific research community.

"Given the broad interest from the Navy in low-cost hydrophones, we were surprised that this design had not been pursued before," says Daniel Freeman, who leads this work in the Advanced Materials and Microsystems Group. "Hydrophones are critical for undersea sensing in a variety of applications and platforms. Our goal was to demonstrate that we could develop a device at reduced size and cost without sacrificing performance."

Essentially an underwater microphone, a hydrophone is an instrument that converts sound waves into electrical signals, allowing us to "hear" and record sounds in the ocean and other bodies of water. These signals can later be analyzed and interpreted, providing valuable information about the underwater environment.

MEMS devices are incredibly small systems — ranging from a few millimeters down to microns (smaller than a human hair) — that are made to have tiny moving parts. This feature allows them to be built into a variety of sensors, including microphones, gyroscopes, and accelerometers. The small size of MEMS sensors has made them crucial in various applications, from smartphones to medical devices. Currently, no commercially available hydrophones utilize MEMS technology, so the team set out to understand whether such a design was possible.

With funding from the Office of the Under Secretary of War for Research and Engineering to develop a novel hydrophone, the team first planned to use microfabrication, an area of expertise at the Laboratory, to develop their device. However, that approach proved to be too costly and involved to pursue. This obstacle led the team to pivot and build their hydrophone around a commercially available MEMS microphone. "We had to come up with an inexpensive alternative without giving up performance, and this is what led us to build the design around a microphone, which to our knowledge is a novel approach," Freeman explains.

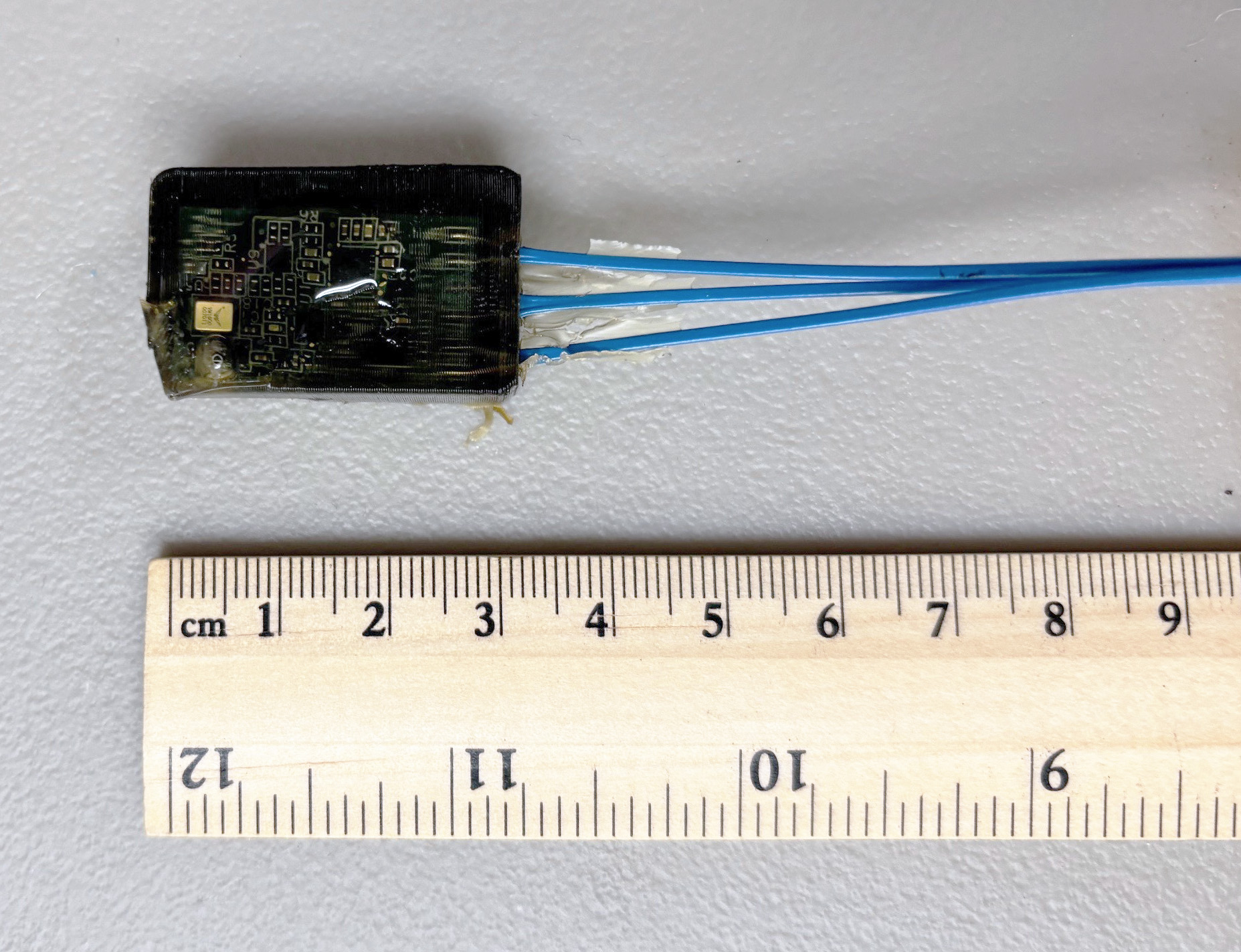

In collaboration with researchers at Tufts University, as well as industry partners SeaLandAire Technologies and Navmar Applied Sciences Corporation, the team made the hydrophone by encapsulating the MEMS microphone in a polymer with low permeability to water while leaving an air cavity around the microphone’s diaphragm (the component of the microphone that vibrates in response to sound waves). One key challenge that they faced was the possibility of losing too much signal to the packaging and the air cavity around the MEMS microphone. After a substantial amount of simulation, design iterations, and testing, the team found that the signal lost from incorporating air into the device was compensated for by the very high sensitivity of the MEMS microphone itself. As a result, the device was able to perform at a sensitivity comparable to high-end hydrophones at depths down to 400 feet and temperatures as low as 40 degrees Fahrenheit. To date, the collaborative effort has involved computational modeling, system electronics design and fabrication, prototype unit manufacturing, and calibrator and pool testing.

In July, eight researchers traveled to Seneca Lake in New York to test a variety of devices. The hydrophones were lowered to increasing depths in the water — 100 feet at first, then incrementally lower down to 400 feet. At each depth, acoustic signals of varying frequencies were transmitted for the instrument to record. The transmitted signals were calibrated to a known level so they could then measure the actual sensitivity of the hydrophones across different frequencies. When the sound hits the hydrophone’s diaphragm, it generates an electrical signal that is amplified, digitized, and transmitted to a recording device at the surface for post-test data analysis. The team utilized both commercial underwater cables as well as the Laboratory’s internally developed fiber-based sensing arrays.

"This was our first field test in deep water, and therefore it was an important milestone in demonstrating the ability to operate in a realistic environment, rather than the water chambers that we’d been using," Freeman says. "Our hope was that the performance of our device would match what we’ve seen in our water tank, where we tested at high hydrostatic pressure across a range of frequencies. In other words, we hoped this test would provide results that confirm our predictions based on lab-based testing."

The test results were excellent, showing that the sensitivity and the signal-to-noise was within a few decibels of the quietest ocean state, known as sea state zero. Moreover, this performance was achieved in deep water, at 400 feet, and with very low temperatures, around 40 degrees Fahrenheit.

The prototype hydrophone has applications across a wide variety of commercial and military use-cases owing to its small size, efficient power draw, and low cost.

"We’re in discussion with the Department of War about transitioning this technology to the U.S. government and industry,” said Freeman. “There is still some room for optimizing the design, but we think we’ve demonstrated that this hydrophone has the key benefits of being robust, high performance, and very low cost.”