Fibers embedded with electronics are putting fabrics to work

Humans wear clothes to serve a few functions — warmth, protection, self-expression, modesty. When we talk about wanting more functional clothing, we might mean pants with bigger pockets or sweatshirts with holes to stick our headphone wires through. But a group of researchers from the Advanced Functional Fabrics of America (AFFOA), Lincoln Laboratory, Inman Mills, and MIT are thinking about functionality of a different scope. They are integrating electronic devices into the very fabric of our clothing.

In a letter recently published in Nature magazine, the researchers describe the first demonstration of embedding semiconductor light-emitting diodes (LEDs) and photodetecting diodes into fibers produced through a thermal draw process. When voltage is applied to the end of the fibers, the diodes embedded inside light up or detect light. The fibers are flexible and durable enough to be woven into a soft textile, machine washed, and handled day to day.

"Fibers with semiconducting materials can deliver sophisticated capabilities never before realized," said Michael Rein, a researcher at AFFOA and lead author of the paper. "Until now, obtaining fibers that encompass semiconducting materials such as silicon or germanium, interfaced with metals in the same fiber, was a challenge due to processing limitations. By incorporating prefabricated devices and micron-sized wires in the thermal draw of the fibers, we were able to demonstrate advanced electronic functionality in fibers."

These electronic fibers start out as a block of polycarbonate called a preform. Tiny diodes — the size of a grain of sand — are embedded down the center of the preform, and copper wire is fed into small channels running down the preform on both sides of the diodes. The preform is then heated up at the top of a draw tower, which pulls the warm, taffy-like substance into a long fiber strand. This stretching spaces out the embedded diodes and forces the wires into contact with them. As a result, hundreds of diodes become electrically connected in parallel inside a single fiber thin enough to be threaded through a needle.

The most compelling aspect of the technology is its applications. The LEDs and photodetectors in the fibers can be used to form a fabric-to-fabric optical communications system — using pulsed light to transmit information from one wearer to another. The team wove LED-embedded fibers into one fabric and photodetecting fibers into another fabric. Placed a meter apart from each other, the photodetecting fabric measured the programmed fluctuations in light intensity emitted from the LED fabric and converted the pattern into an electrical signal. The team says the communication range of the system can be increased by designing the fiber cladding as a lens to align and focus the LED light.

The fibers also have biomedical applications. Simply wearing clothing woven with these fibers could allow a person to monitor their heart rate, for example. If a person places a finger over an LED fiber and photodetecting fiber woven next to each other in the same fabric, the photodetecting fiber can record the changes in light intensity being reflected off the finger as blood circulates in vessels close to the skin. This signal can then be used to determine the wearer's heart rate.

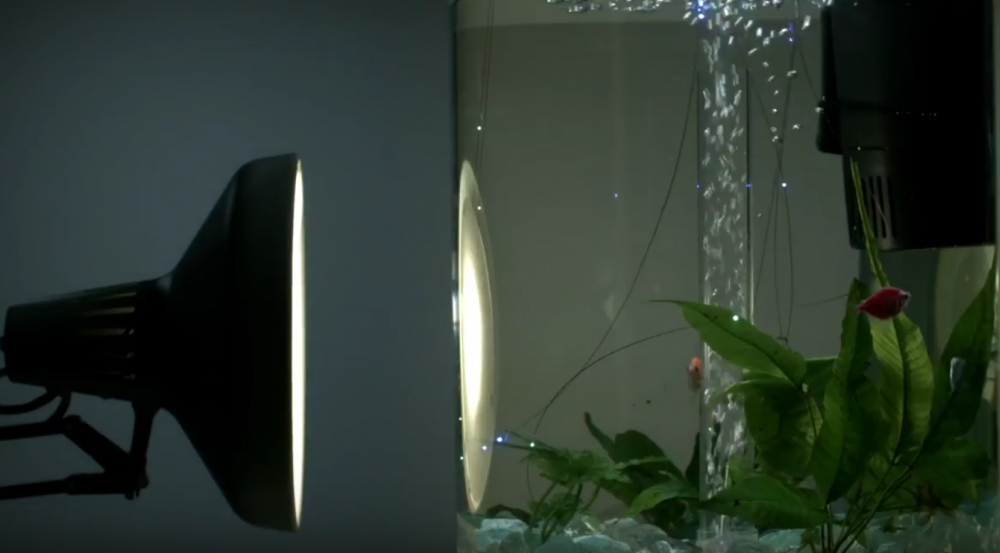

A side benefit of this new device-embedding technique is that the electrical components of the fiber are inherently waterproofed by the polycarbonate they're enclosed in. The components work even when submerged in water for weeks. To demonstrate this capability, the researchers put the fibers in a fish tank and used a lamp outside of the tank to send pulsed light signals to the photodetecting fibers. The detectors converted this optical signal into an electrical signal, which was then converted to an audio signal — Handel's "Water Music" was transmitted. The fibers worked just as well after several wash cycles too.

Much of this work was conducted at the Defense Fabric Discovery Center (DFDC) at MIT Lincoln Laboratory. The center, which opened last fall, is a space for staff from the Laboratory, the Natick Soldiers Systems Center, AFFOA, and industry and government organizations to collaborate on the development of functional fibers and fabric systems that can also serve defense needs.

Alexander Stolyarov, an author of the Nature paper and leader of the DFDC, said that the partnership "lets us find applications for emerging technologies early in the development process; moreover, it allows the deliberate guiding of the technological evolution from a systems perspective."

The fibers are already being considered for integration into military uniforms. AFFOA, meanwhile, is working to transfer the technology to consumer industries for commercialization. Funding for AFFOA, and the DFDC through AFFOA, was provided in part by the federal government and the Commonwealth of Massachusetts to spur growth in the textile manufacturing industry. Inman Mills, a fabric manufacturer and collaborator in this project, has developed a process to weave the fibers into a polyester fabric by using a conventional loom.

The embedding technique is not limited to the incorporation of diodes into fibers. Researchers at the DFDC are now using the technique to similarly integrate temperature-sensing devices into fibers. The team wants to use these fibers to measure, along different points, the skin temperature of people who are working in extreme heat or cold. "The next step is to integrate this temperature-mapping capability into gloves for use in an arctic environment," said Lauren Cantley, a postdoctoral associate in the Chemical, Microsystem, and Nanoscale Technologies Group. The goal is to prevent injury; the gloves could warn wearers, for example, if their fingers are at risk for frostbite.

Additional research is building on this technique — the team views it as an opening of a flood gate into fibers with various embedded electronics, and with those, fabrics that deliver system-level functionality. The days when a shirt was just a shirt may soon be in the past.

"This approach enables a path to integrate various electronic devices in thermally drawn fibers that we've coined as the 'Moore's law' for fibers," said Rein. "A full electronic fiber–based garment is within reach."

Related:

State grant will support advanced fiber and fabric research at Lincoln Laboratory

Lincoln Laboratory celebrates the opening of the Defense Fabric Discovery Center