Fiber Sensor Array Buoy

MIT Lincoln Laboratory, in partnership with the Advanced Functional Fabrics of America (AFFOA), is leveraging experience in fabricating kilometer-length fibers with embedded electronics to develop fibers that can operate in the ocean. Researchers are exploring how the fibers may enable a small, low-cost system that provides persistent monitoring of the undersea environment. This system would advance an understanding of the ocean's evolving dynamics by providing rich, direct measurements of their influences in real time.

Motivation

Understanding and predicting the dynamics of the ocean are vital for naval operations that must maintain awareness of the maritime environment and for scientific research that examines the effects of climate changes on the ocean ecosystem. The vastness of the ocean and its constantly changing nature make measurements of the ocean's characteristics not only difficult but also costly (civilian research vessels cost ~$50K/day to operate). Currently, the availability of persistent measurements is constrained to data acquired by expensive satellites, a limited number of slowly moving floats and instrumented buoys, and roughly 100 shipboard monitors. The quantity and timeliness of all these measurements are insufficient to achieve a high degree of forecast accuracy and reliability.

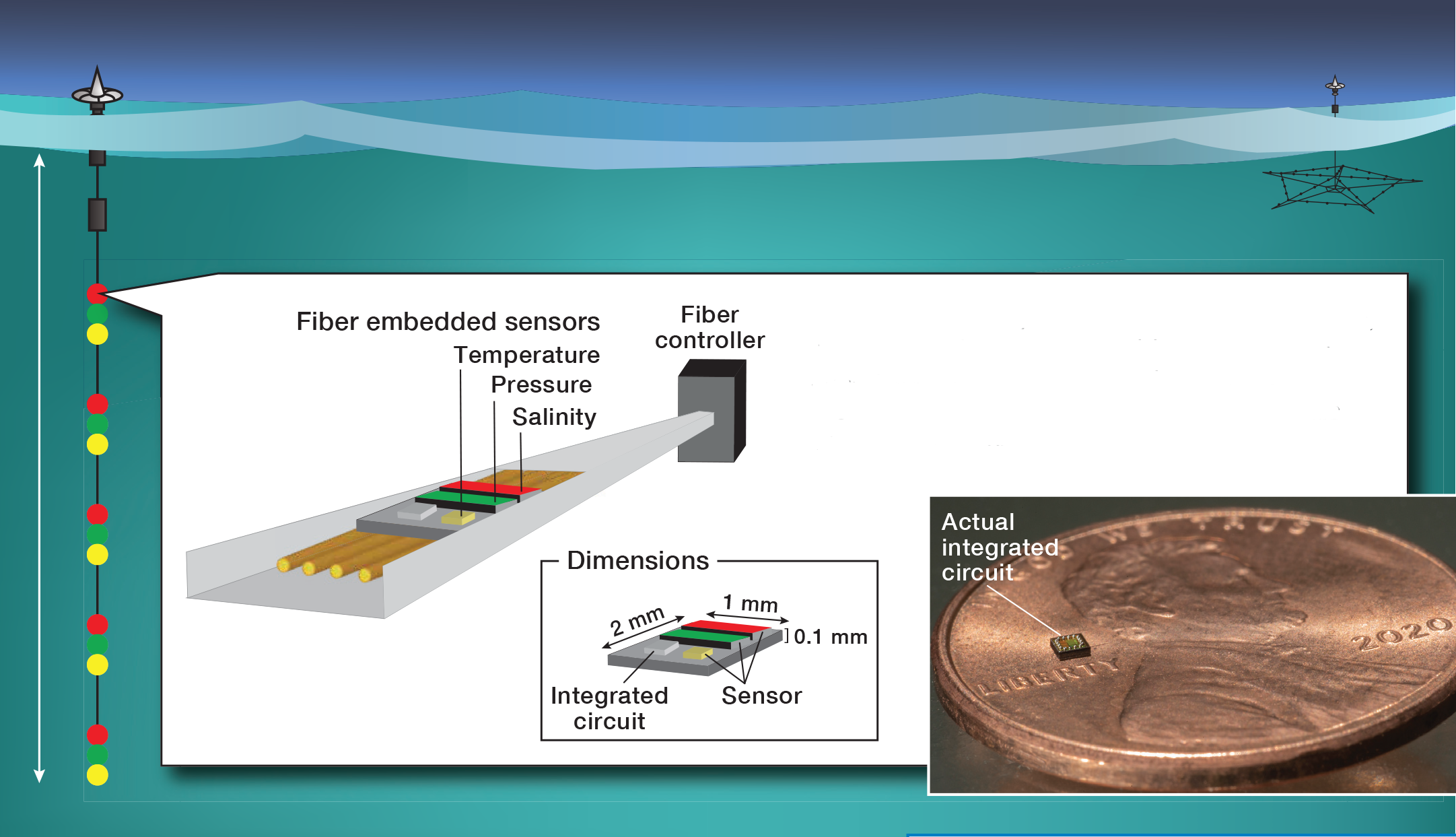

A fiber sensor array measures ocean temperature, pressure, and salinity to provide an estimate of sound speed versus depth. This sound speed profile will be used to interpret acoustic signals detected in the sonobuoy.

Concept

Arrays of sensors could enable persistent measurements over wide ocean areas. To address the need for low-cost, low-SWaP sensor arrays, Lincoln Laboratory is developing a novel approach to embedding electronics into long-length polymer fibers. Our researchers draw these fibers by heating a block of polymer and pulling it to kilometer lengths. During the draw process, copper wires are fed into the interior of the fiber, resulting in a fiber with a copper bus, which is a key enabler for the arrays. This bus delivers power and data to sensors that are integrated into the fiber after the draw through a customized process for soldering and encapsulation. At the fiber's end are electronics that individually address each sensor, store the data, and wirelessly transmit the data to aircraft, ship, or satellite. This technology has potential for addressing the needs of not only undersea monitoring, but also ground and space-based applications.

Benefits

- A compact custom-designed integrated circuit enables millimeter-scale sensing nodes

- Embedded electronics support multiple sensors making simultaneous measurements of undersea characteristics

- The system is designed to make measurements every few seconds to provide a complete profile of the upper kilometer of the ocean, where almost all its variability occurs

Potential Use Cases

- Monitoring the dynamic ocean environment

- Scientific understanding of evolving ocean dynamics

- Forecasting of ocean effects

Additional Resources

MORE INFORMATION

For more information on Lincoln Laboratory’s fiber sensing technology, see the news story "Fibers embedded with electronics are putting fabrics to work" on the Laboratory’s website.