3D-printed shielding can help protect satellites from radiation damage

In 2021, Lincoln Laboratory's Technology Office and the Advanced Prototype Engineering Technology Symposium partnered to offer the Technologies to Enable Future Space Challenge. The aim was to challenge the Laboratory community to generate novel ideas that advance the nation's capabilities to design, build, and field advanced systems and concepts that meet the needs of future space missions. Altogether, Laboratory staff submitted 29 proposals for technologies and prototypes of future space systems before the winning proposal — 3D-Printed Shielding for High-Performance Radiation-Hardened Satellites — was selected.

Space is a harsh and unforgiving place, particularly for electronic systems. Galactic cosmic rays, radiation, and other high-energy sources cause damage to electronics, resulting in shorter mission times and reduced capabilities for space systems. This technology aims to make satellites more resistant to these threats.

"This program, if successful, will allow the Department of Defense to use virtually all integrated circuit technologies in extreme radiation environments, such as space, by shielding commercially available electronics from destructive radiation," says Bradley Duncan, a technical staff member in the Advanced Materials and Microsystems Group and the lead investigator of the winning proposal.

While other approaches to mitigate radiation damage in space exist, they result in an increase in size and cost, and they prevent the use of state-of-the-art technologies. By contrast, 3D-printed shielding allows for the fabrication of conformal and tightly integrated shielding that conventional manufacturing cannot produce, and that can support the latest microelectronic technologies. "By printing custom shield architectures directly onto electronics, we can potentially enable the most advanced commercial off-the-shelf electronics to exist in space environments," says Devon Beck, an associate staff member in the same group.

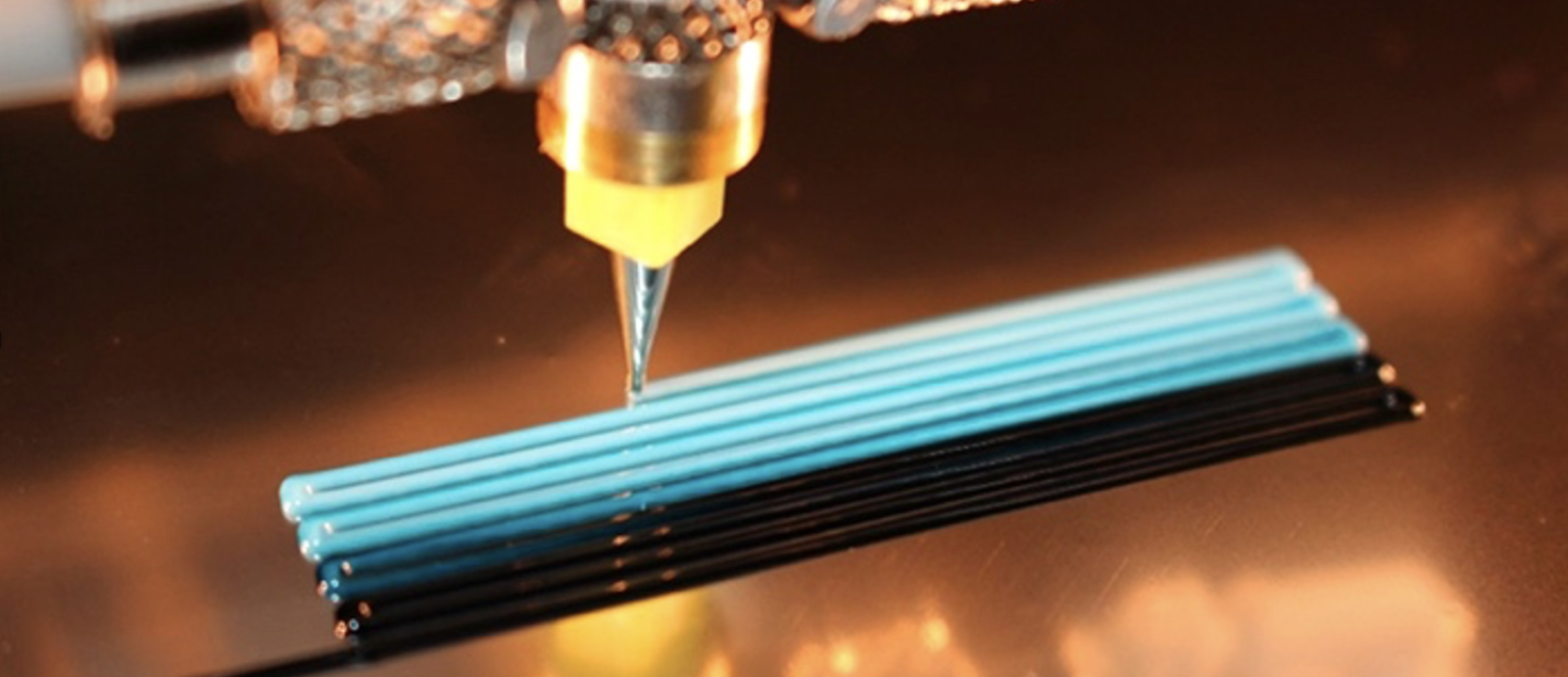

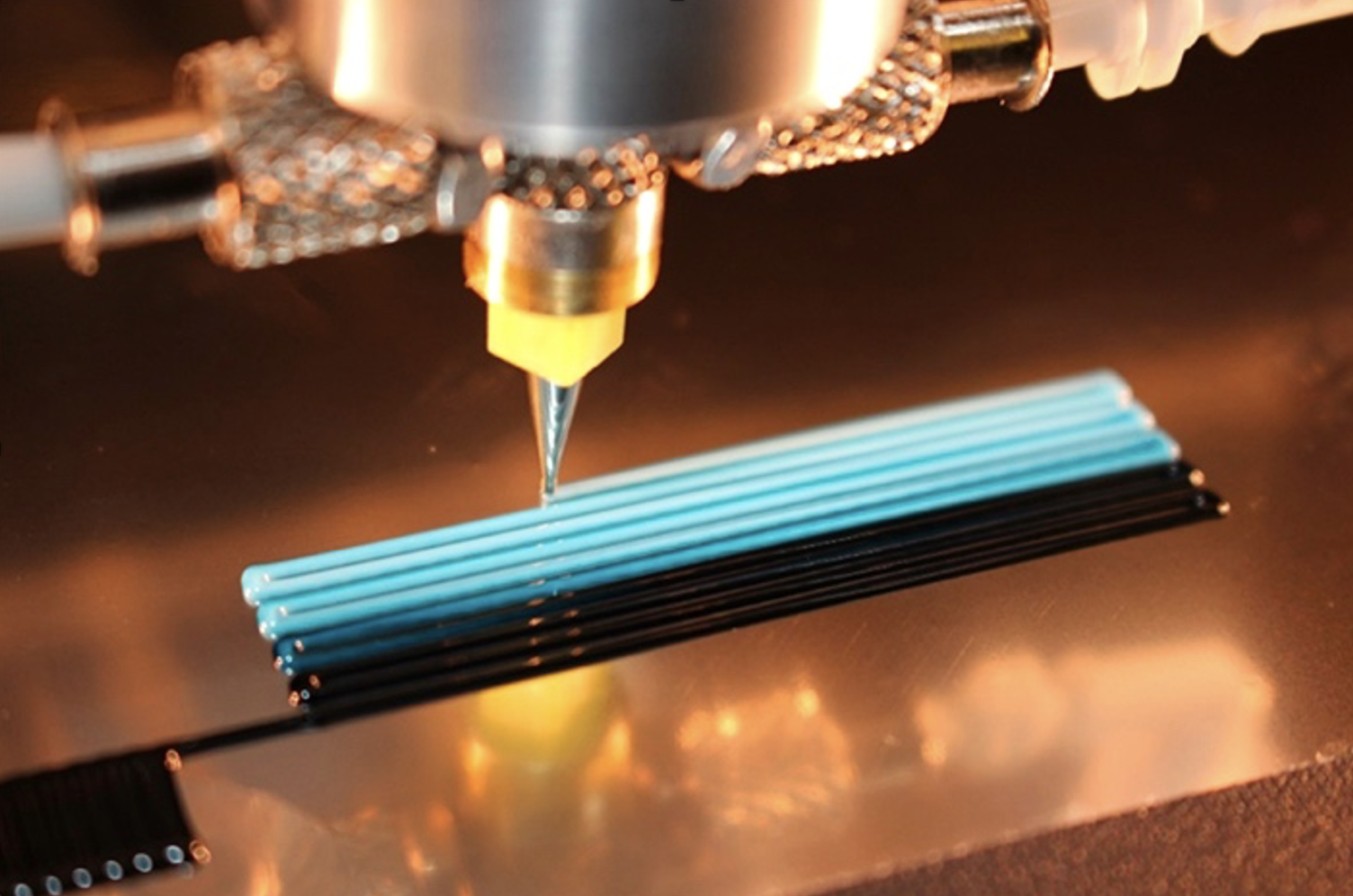

The researchers' 3D-printing process deposits paste-like materials directly onto satellite components in a conformal manner using a robotically controlled printhead. Materials are extruded out of small nozzles, creating self-supporting filaments that are built up to form the shielding. This shielding provides additional protection against radiation damage. Early work on radiation shielding studies was spearheaded by Jacob Bickus, a former military intern who has since graduated with a master's degree in nuclear engineering from MIT.

"This is another instance where a military fellow was able to contribute to intellectual property," says Melissa Smith, an assistant leader of the group. "We really enjoy working with the military fellows and providing opportunities for their ideas to have long-lasting impacts in support of national security."

The program is also a follow-on to Technology Office–funded research that investigated the development of low-cost picosatellites fabricated in a silicon foundry. During this research, the researchers sought to miniaturize all of the components, including radiation shielding, and discovered that their approach proved useful for improving resiliency while reducing the size and mass of other small satellites.

The team has submitted a technology disclosure in hopes that their technology can be transitioned to industry. They also aim to collaborate across the Laboratory to identify additional opportunities to implement this type of radiation shielding for system capability enhancements.

"This project exemplifies the Laboratory’s mission and focus on developing advanced technologies and enhanced capabilities to meet the evolving needs of the Department of Defense," says Pascale Gouker, a senior staff member in the group. "3D-printed shielding will be a disruptive innovative approach to producing high-performance radiation-hardened micro-systems."