Materials by Design

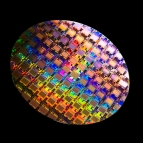

Many technology areas today are either fundamentally limited by current materials or could be improved by a new material with more advantageous properties. One example is the field of microelectronics — after 40 years of improvement in transistor cost and size, progress is slowing due to the physical limits of silicon. To continue progress, a new material is likely needed.

But materials discovery is a slow process, accomplished through experimentation or theoretical prediction. On the experimental side, it is typical to only investigate small modifications to existing materials using a “guess and check” approach, which greatly limits the breadth of materials that can be analyzed. Materials discovery via theory is typically driven by academic curiosity and focused on improving a single functional property without regard to a specific application goal.

The Materials by Design program is a joint effort between the Advanced Materials and Microsystems Group and the Artificial Intelligence Technology Group to expedite the materials discovery process by establishing close connections among mission goals, systems analysis, materials theory, synthesis, and characterization. The approach begins with a mission objective that could potentially benefit from a new material. Thorough systems analysis is applied to determine whether seeking a new material is likely to yield performance improvements and to establish the parameters of new candidate materials. Through an iterative process, candidate materials are screened using machine learning (ML) algorithms and validated with theoretical calculations to select top candidate materials from a pool of hundreds of thousands of compounds. The most promising compounds are then synthesized and characterized to validate ML and theory predictions.

Today, we are applying our approach to several specific materials needs. In one application, we have discovered new materials suitable for an ultrafast reflective shutter needed for weather-penetrating lidar. We are also developing new materials for windows in high-temperature environments. Recently the program was expanded to include development of high-throughput synthesis and characterization platforms, as well as AI-guided additive manufacturing processes. Beyond specific system-level applications, our goal is to offer a new, generalized approach to accelerate the deployment timeline of new, mission-specific materials from decades to months.