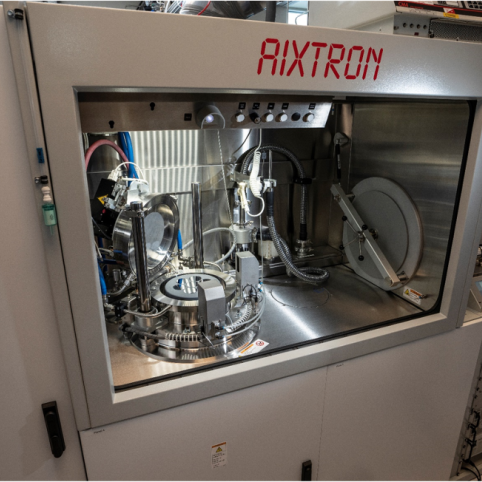

- III-P/As/Sb epitaxy for optoelectronics heterostructures

- Close-coupled showerhead geometry

- Top-side pyrometric temperature control

- In situ reflectance and wafer curvature measurement

- Flexible wafer configurations from 7 x 2 in to 1 x 200 mm

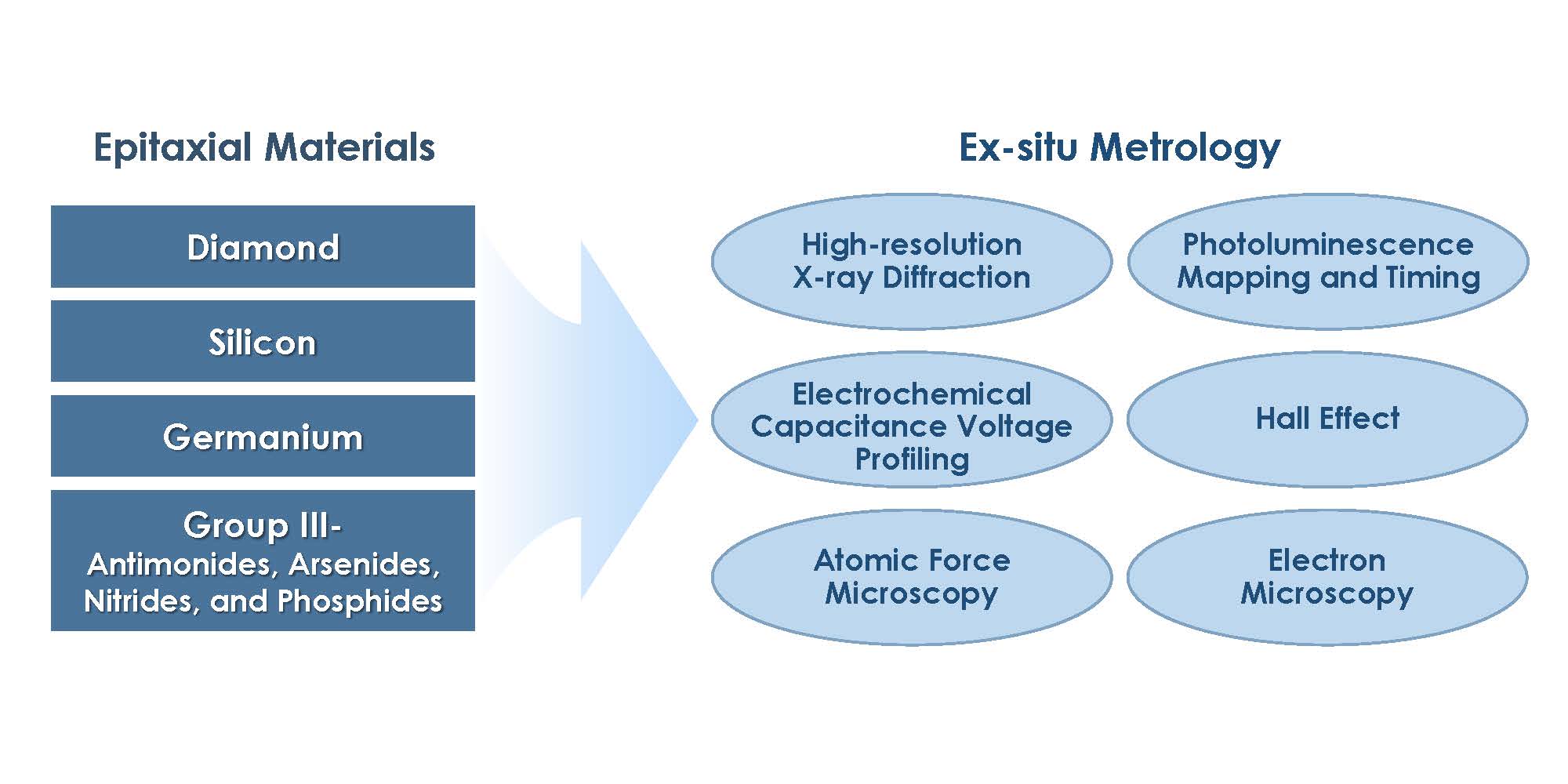

Materials

The Microsystems Prototyping Foundry has broad material systems capabilities for technology development in the electric, photonic, and quantum domains.

Compound Semiconductor Epitaxy

Aixtron CCS R&D Metal-Organic Chemical Vapor Deposition (MOCVD) Reactor

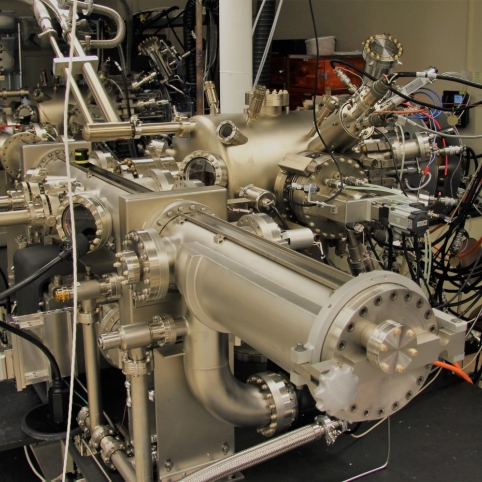

Dual Veeco MOD GEN II Molecular Beam Epitaxy (MBE) Reactors

- III-/As/Sb/Bi epitaxy for optoelectronic heterostructures

- Temperature monitoring via

- Band-edge thermometry

- Variable wavelength pyrometry

- Black body emission

- In situ reflection high-energy electron diffraction (RHEED)

- Al, Ga, In, As, Sb, Bi, Si, Be, and GaTe effusion cell sources

Silicon and Germanium Epitaxy

ASM Epsilon MOCVD Epitaxy

- 200-mm cassette to cassette

- Group 4 growth with P & N doping

- Si epitaxy for novel FET geometries

- Ge epitaxy on Si substrates

- SiGe epitaxy

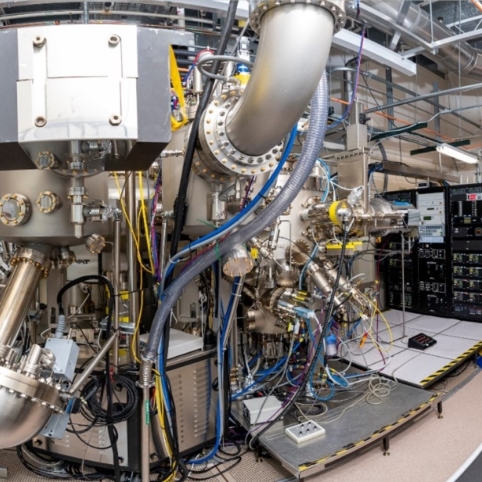

Veeco GEN200 Molecular Beam Epitaxy

- Growth:

- 2 e-beam sources

- 5 effusion thermal sources

- 8 elements and counting: Al, B, Mo, Nb, Re, Sb, Si, Ta

- Analysis:

- Beam flux monitor

- Reflection high-energy electron diffraction (RHEED)

- Electron impact mission spectroscopy

- X-ray photoelectron spectroscopy

Contact us

Learn more about the capabilities and opportunities in the Microsystems Prototyping Foundry.