Superconducting Discrete Integrated Circuit Electronics

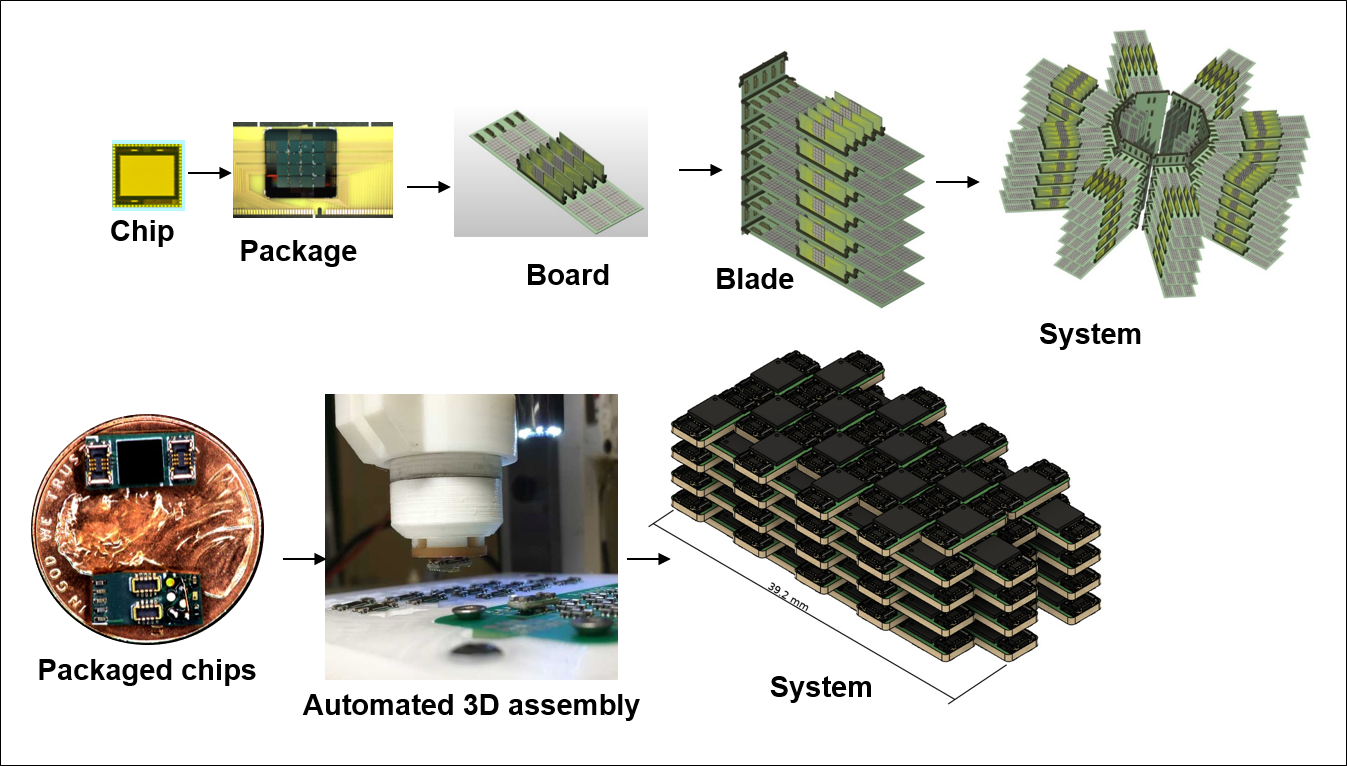

Researchers in the Quantum Information and Integrated Nanosystems Group are exploring an alternative to the traditional approach for designing and building integrated system architectures. Typically, systems such as high-performance computing systems and reconfigurable 3D sensor arrays have been hierarchically built up from chips, to packages, to boards, to blades, and finally to systems. Our Superconducting Discrete Integrated Circuit Electronics (Super-DICE) project is leveraging the Laboratory’s superconducting electronics infrastructure and MIT’s Center for Bits and Atoms DICE technology platform to develop discrete nodes (i.e., packaged chips or modules) that can be 3D-assembled (like LEGO bricks) to create different system architectures.

The Super-DICE technology allows system developers to combine modules produced by trusted foundries and commercial manufacturers to create highly secured, cost-effective systems. This kind of mix-and-match of modules may deliver yield enhancements, as well as power and performance benefits, to many mission-critical Department of War systems.

The end-to-end Super-DICE workflow includes performance projections, package fabrication, programming compilers, conventional and robotic assembly, and a design for both logical and physical placement of nodes. The Super-Dice development path has the potential to reduce time and costs, minimize vulnerabilities in supply chains, decrease waste through reusability of parts, and support improved system integration and novel form factors.