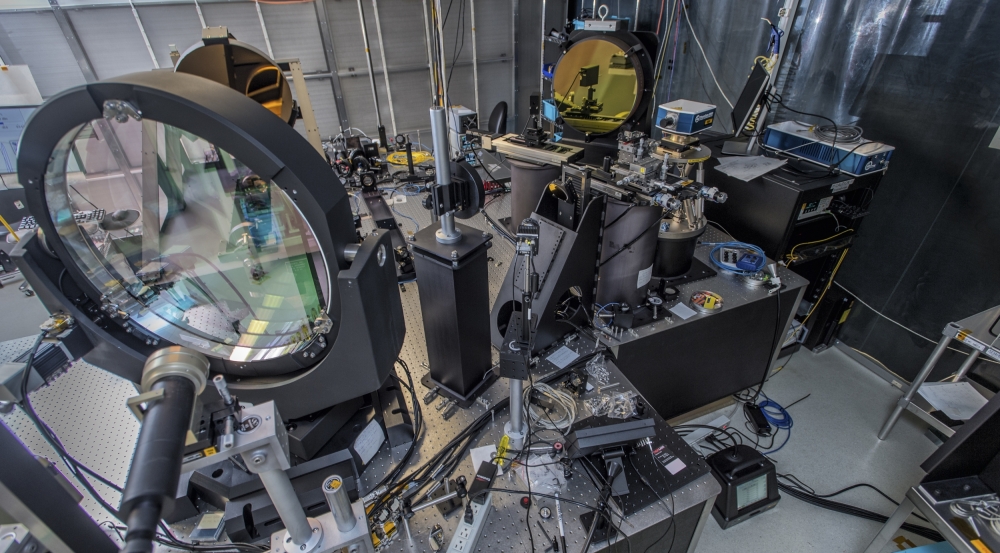

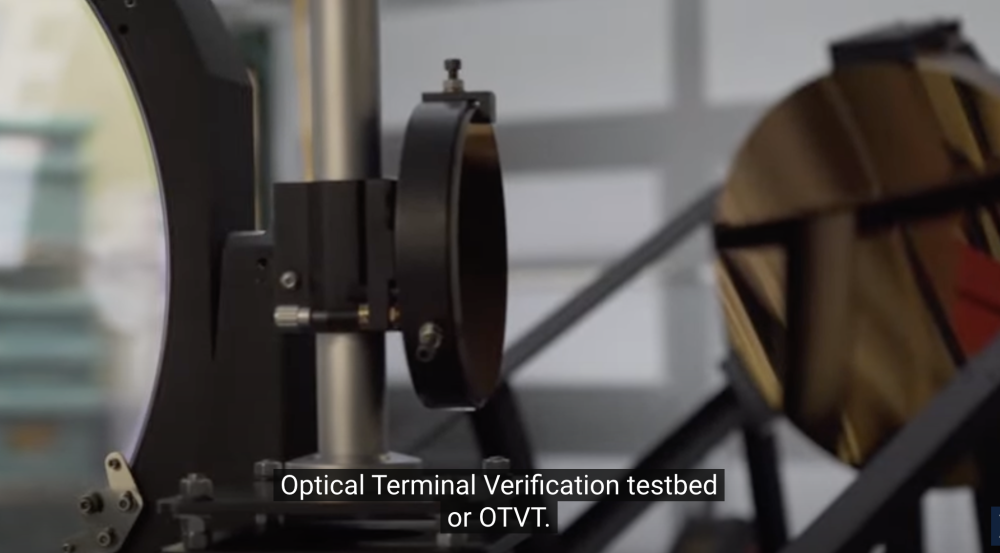

Optical Terminal Verification Testbed

Lincoln Laboratory built the OTVT, which became operational in 2005, to fill a specific national capability gap: providing unbiased, trusted assessments of laser communications terminals. Currently, various organizations are drafting standards for laser communications terminals to ensure robust, interoperable networks. The U.S. government leverages OTVT to assess the interoperability of third-party terminals, while Laboratory staff use OTVT to test new, in-house-developed terminal designs. Overseen by a highly experienced team, the OTVT offers high-quality optics and well-calibrated instrumentation to ensure quality measurements of terminals with a broad range of laser beam diameters and output power levels.

Terminals can be tested for their overall performance and for their performance at the level of individual components: communications modems; optics; and pointing, acquisition, and tracking (PAT) systems. Such testing can be performed under emulated impairments that the terminal would experience when fielded, such as terminal jitter, so that its performance can be assessed in a realistic environment.

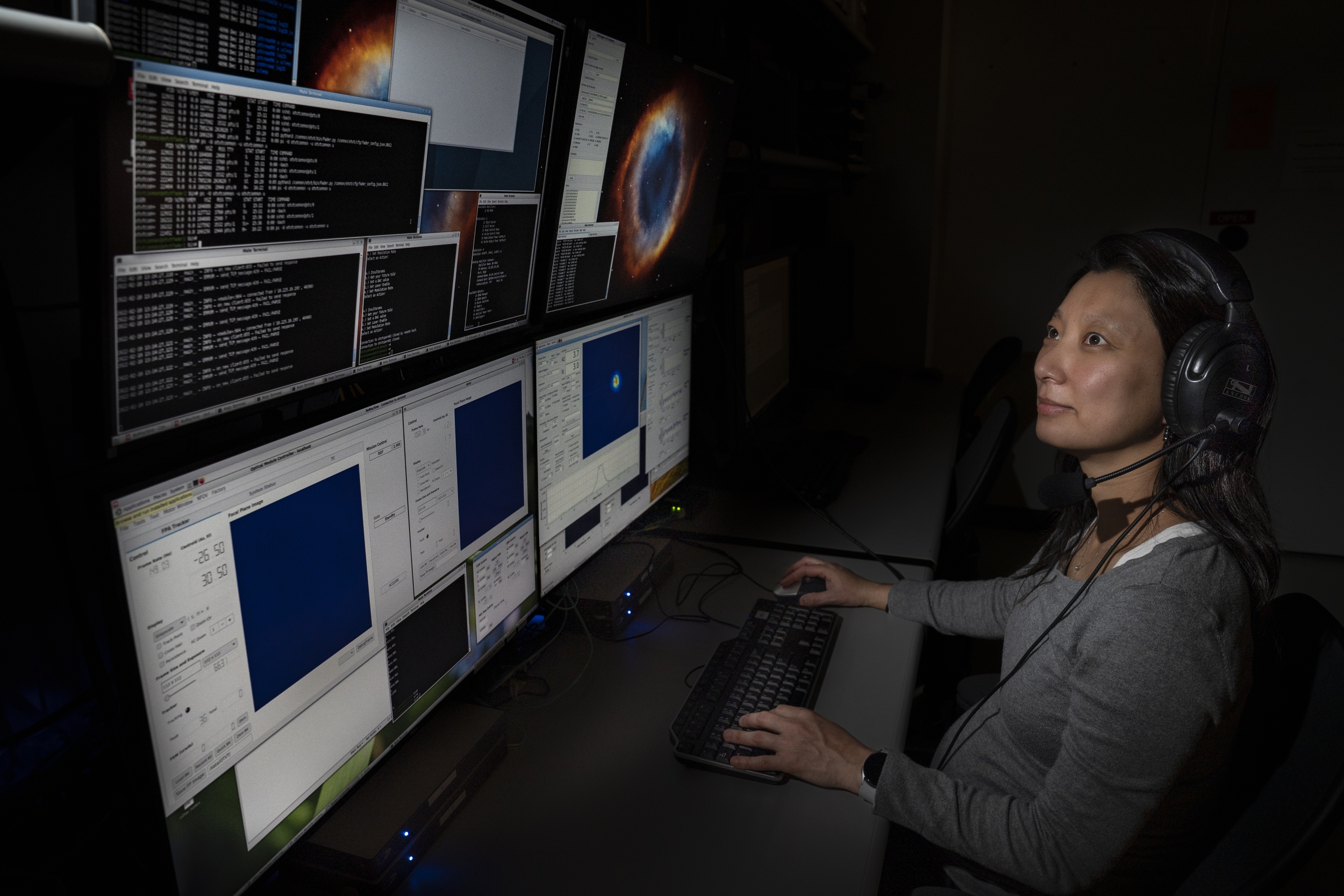

Terminals can be tested at various stages of maturity, from early subsystems through deliverable flight units. Test campaigns have helped stakeholders understand the limitations of their proposed terminal designs, enabling them to implement and verify improvements to the underlying hardware and software. The OTVT has hosted teams from major aerospace prime contractors and NASA, and has played a significant role in supporting cutting-edge laser communications programs.

Over the past five years, Lincoln Laboratory has significantly refreshed OTVT so that it can continue to serve as a premier national asset for years to come. Two major improvements are software automation and a fiber-optic switch matrix for repeatedly and reliably interconnecting various sources, components, and instruments. Together, these capabilities help mitigate human error during testing, especially considering the many different test configurations available, and reduce the time and variability associated with manual reconfiguration. Other enhancements include an upgraded airflow control and air filtration system for the OTVT clean tent; a more flexible and scalable PAT system supported by a dedicated high-performance computer and new suite of OTVT-developed software; and a reliable, highly secure enterprise-grade network for operators to conveniently command the OTVT and collect measurements.