Virtual Integration Technology Lab

The Virtual Integration Technology Lab (VITL) provides a space for Laboratory engineers and scientists to develop advanced healthcare technologies. Through virtual collaboration, clinical partners are invited to provide essential feedback continuously through the engineering process. With a unique focus on pre-hospital care, this space supports the rapid prototyping of new medical devices and adaption of existing technologies to address critical clinical needs.

Operated by the Human Health & Performance Systems Group, this laboratory space is equipped to support a quick-turn, iterative prototyping approach to early stage medical device development. VITL includes capabilities for the design of electrical and mechanical components, mechanical fabrication, and electronics assembly and testing. Developers can also assemble system-level prototypes and perform initial device demonstration and user testing on medical phantoms, designed to mimic human tissue. Throughout the prototyping processing, VITL supports a virtual connection to clinical collaborators, who are able to provide real-time feedback on component design trade-offs and observe system prototype evaluations.

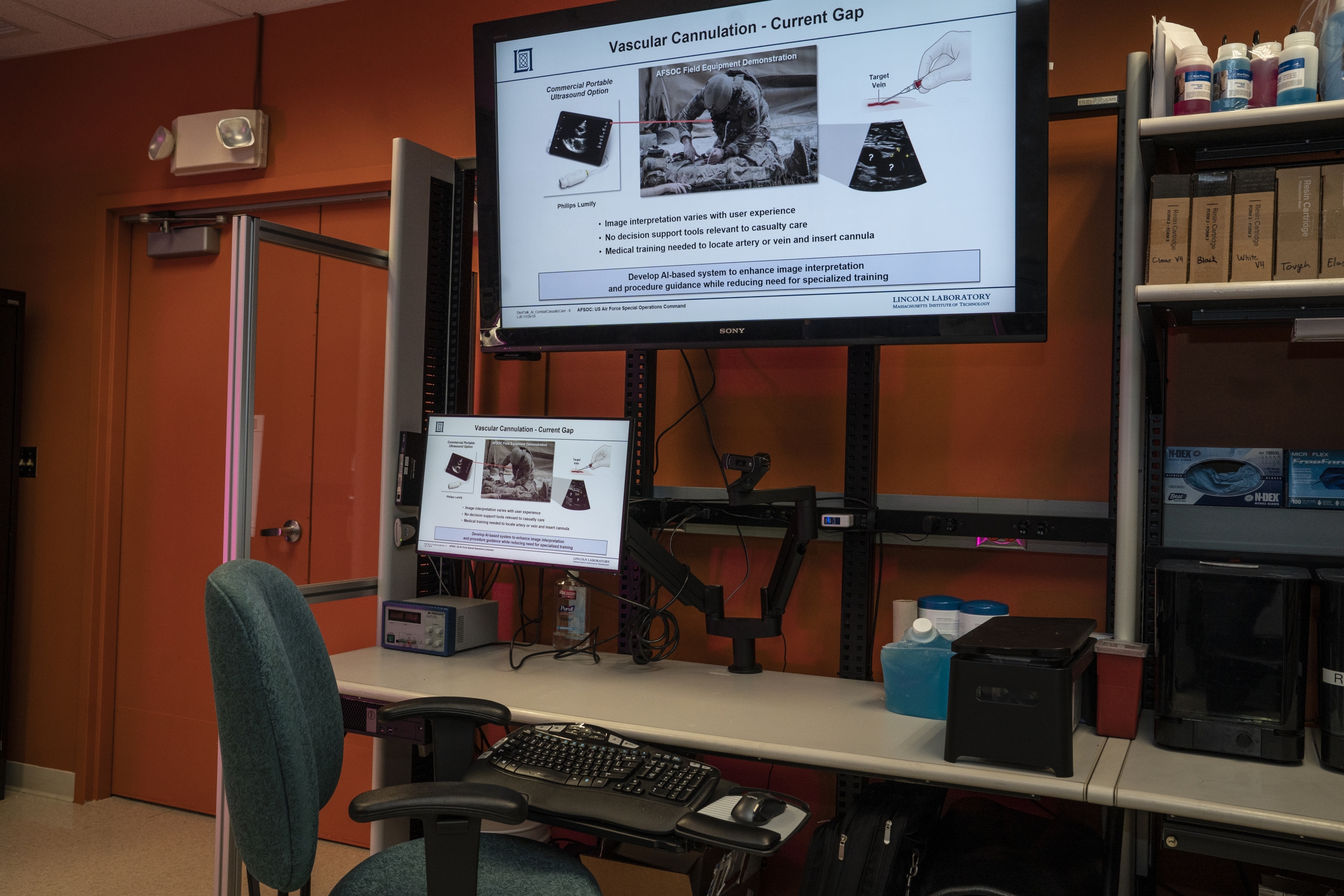

Recently, Laboratory researchers and clinicians from Massachusetts General Hospital collaborated through the VITL to develop the Artificial Intelligence-Guided Ultrasound Intervention Device (AI-GUIDE). This portable platform technology enables a user with minimal training to quickly catheterize a major blood vessel at the site of an injury, which is the first step in providing live-saving treatment for an internal hemorrhage.