Low-Cost High-Vacuum Pump

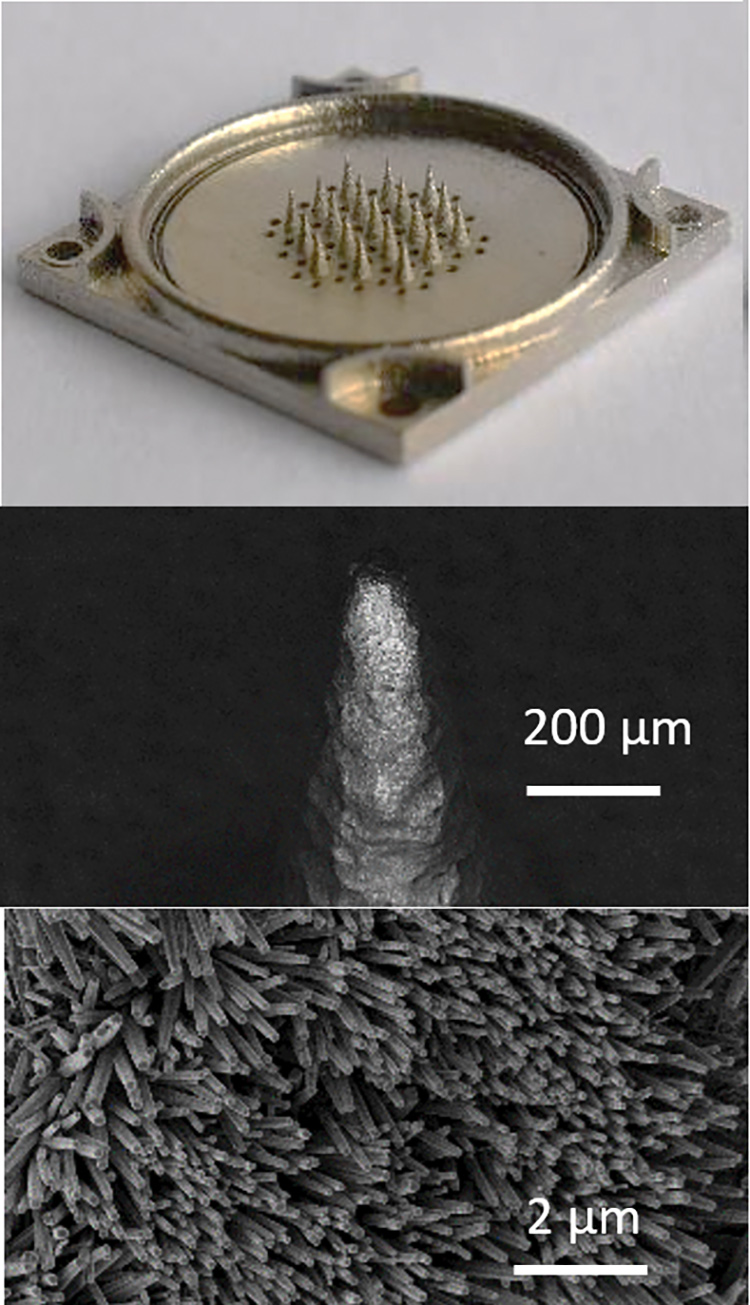

Researchers at Lincoln Laboratory and MIT's Microsystems Technology Laboratories are experimenting with the design of a small, high-vacuum pump that will use an array of additively manufactured (i.e., 3D printed) "needles" to spray an ionized, nonvolatile liquid into a chamber, generating ample air movement that will result in the creation of a vacuum. The ultimate goal of the project is to develop a low-cost vacuum pump that will enable a portable mass spectrometer to achieve high-performance chemical detection.

This new pump design offers an advantage for a mass spectrometer: a working liquid with essentially zero vapor pressure that could facilitate pumping to extremely low pressures. The lower the pressure achieved, the better the spectrometer performs. Currently, most precision spectrometers use large turbomolecular vacuum pumps (or, succinctly, turbopumps) that deliver high-sensitivity detection and accurate identification of chemicals. However, these pumps are expensive because of the fine machining needed to achieve the tolerances required of the turbopumps' high-speed spinning blades that generate the rapid air movement. Turbopumps are also susceptible to malfunction and damage from even slight vibrations. The electrospray concept uses no moving parts, eliminating costly machining and mitigating vulnerability to vibrations, and the needles are manufactured of inexpensive, durable plastic polymer. This novel pump's performance has been evaluated via simulation, and its prototype is being fabricated at MIT for testing at Lincoln Laboratory.