Low-Temperature Additive Manufacturing of Glass

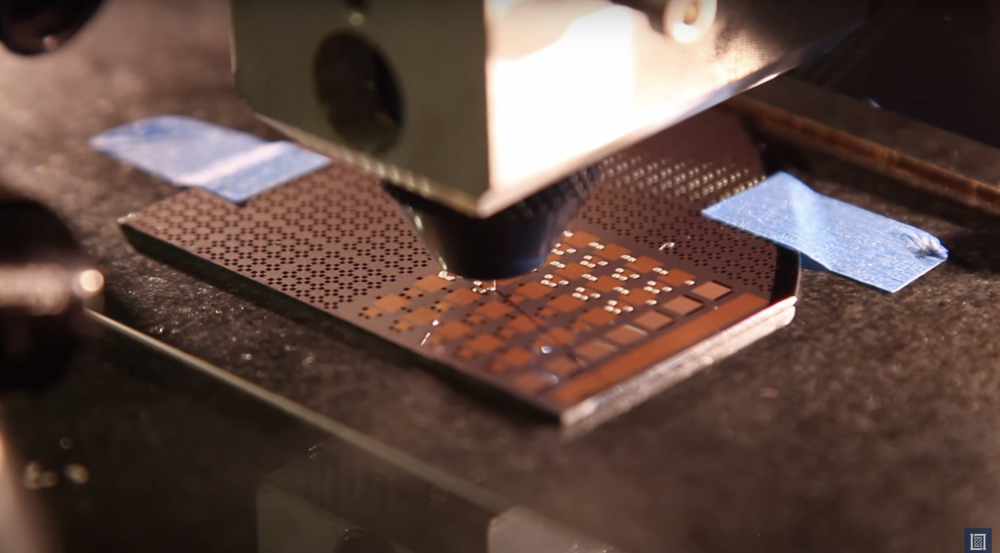

Additive manufacturing (3D printing) holds promise for fabricating complex glass structures that would be unattainable with traditional glass manufacturing techniques. Lincoln Laboratory’s low-temperature technique could facilitate the widespread adoption of 3D printing for glass devices such as microfluidic systems, free-form optical lenses or fiber, and high-temperature electronic components.

Additive manufacturing has expanded the ability to rapidly and cost-effectively create system components. However, traditional materials — various plastic and metal composites — can produce 3D printed structures with mechanical, chemical, and thermal instabilities. Using inorganic composite glasses solves many of the instability issues and offers a promising approach to create structures with diverse shapes and properties. However, the high temperatures (greater than 1,000°C) typically used to sinter (harden) glass items have hindered the use of glass in 3D printing. High-temperature processing requires specialized equipment and is incompatible with temperature-sensitive materials and components.

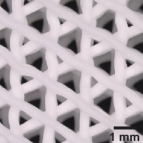

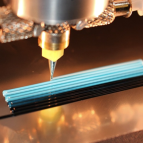

Lincoln Laboratory has demonstrated viable low-temperature 3D printing of glass structures. The process uses the direct ink writing technique to extrude, layer by layer, the Laboratory-developed multimaterial glass ink (composed of a silicate solution and nanoparticles of other inorganics) into the desired form. The process is done at room temperature. To ensure structural stability, the item is cured in a mineral oil bath heated to just 250°C. Following heat treatment, the structure is rinsed in an organic solvent to remove residual mineral, leaving a fully inorganic silica item.

Learn more about how to access this technology or explore other core capabilities in our Microsystems Prototyping Foundry.